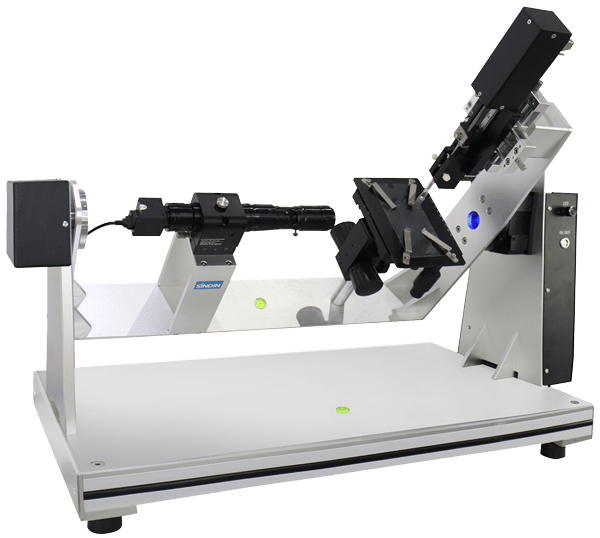

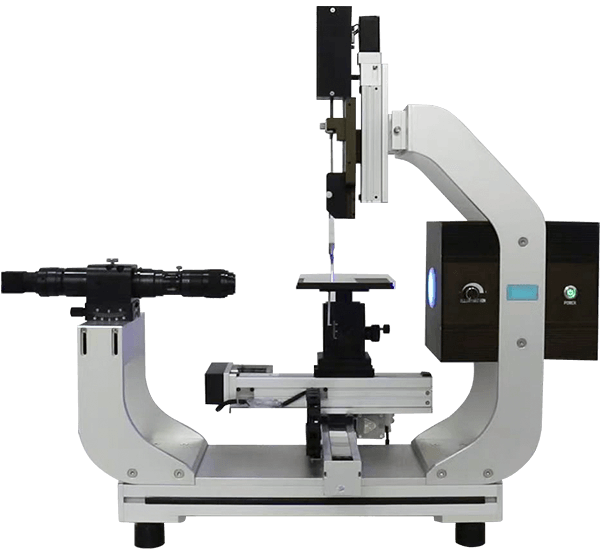

Fully Automatic Contact Angle Measuring Instrument

- Product Number:LD-JC3

- Product Difference:Fully automatic type, compatible with automated assembly lines for online fitting

Product Introduction

The contact angle refers to the angle θ formed between the tangent line to the gas-liquid interface at the triple point of gas, liquid, and solid, and the solid-liquid boundary line on the liquid side. Contact angle measurement is currently the primary method for assessing surface properties.

The LD-JC3 Fully Automatic Contact Angle Meter employs shape image analysis to measure sample surface properties including contact angle, wetting performance, surface interfacial tension, surface energy, rolling angle (slip angle), advancing/receding angles and hysteresis, as well as multi-point automatic intelligent contact angle measurement. This highly automated equipment can integrate with automated production lines for in-line fitting.

Fully automatic contact angle meters are widely applied across diverse industries. In sectors such as mobile phone manufacturing, glass production, surface treatment, materials research, chemical engineering, semiconductor fabrication, coatings and inks, electronic circuits, textile fibers, and medical biotechnology, contact angle measurement has become a crucial instrument for evaluating surface properties. (Certain testing functions require optional accessories.)

1. Wetting behavior of liquids on solid surfaces (spreading, penetration, absorption), measured using the sessile drop method for static contact angles;

2. Measurement of advancing angle, receding angle, contact angle hysteresis, rolling angle, and dynamic contact angle on solid surfaces;

3. Continuous real-time analysis and process recording of absorption materials, including time-dependent contact angle curve analysis;

4. Contact angle measurement for various specialty materials such as powders, curved surfaces, and superhydrophobic/superhydrophilic samples;

5. Contact angle testing of materials immersed in liquids using the attached drop method;

6. Measurement of surface tension and its polar and dispersive components for various liquids using the free drop method;

7. Calculation of solid surface free energy and analysis of its polar and dispersive components;

8. Analysis of liquid adhesion work on solid surfaces to evaluate surface uniformity and cleanliness;

The contact angle measuring instrument primarily consists of five major components: light source, injection unit, sample stage, acquisition system, and analysis software. The device operates based on optical imaging principles.

① Light source employs a dense LED cold light design, delivering uniform illumination, clear images, and extended lifespan;

② Injection unit utilizes a high-precision syringe pump for liquid delivery, controlled by software for quantitative and constant-speed operation, ensuring stable droplet formation with high accuracy; the unit automatically ascends and descends for liquid contact;

③ Sample stage incorporates a three-dimensional automatic displacement device, fully software-controlled, enabling automatic positioning and measurement at designated points; different test protocols can be configured for various products;

④ The acquisition system employs an imported monochrome CCD camera for stable, clear, and reliable imaging. The lens utilizes an imported German industrial-grade telecentric zoom configuration with 0.7-4.5x magnification, 3mm fine adjustment, and distortion-free imaging;

⑤ The analysis software offers powerful functionality, including one-click fully automatic fitting capabilities. It incorporates internationally advanced fitting methods to achieve precise fitting for various droplet morphologies.

Product Features

The main unit features a high-strength aerospace aluminum alloy structure combined with a modular design concept. It employs independently developed integrated chip circuit control and incorporates the design essence and configuration of internationally superior imported contact angle equipment, ensuring exceptional instrument stability.

It utilizes the world's most advanced contact angle analysis methods, enabling precise fitting for all types of droplet imaging. This includes Hengmei's proprietary differential ellipse and differential circle methods for specialized liquid imaging fitting.

An industrial-grade, densely adjustable LED cold light source system (lifespan exceeding 25,000 hours) ensures clearer imaging while preventing small droplet evaporation caused by excess heat.

Utilizing a high-performance, Japanese-imported industrial motor and an industrial-grade telecentric zoom lens, it achieves virtually distortion-free imaging for optimal results.

As China's first provider of German-imported contact angle calibration samples, we ensure instrument precision with angle calibration standards: 3°, 5°, 8°; 60°, 90°, 120°; 115° (optional).

Features rapid bilateral contact angle measurement fitting for comprehensive analysis of liquid-solid surface wetting properties and accurate assessment of actual surface wetting conditions.

The flexible acquisition system design accommodates most measurement environments, easily handling complex sample surface measurements.

Dynamic imaging and video rapid testing capture continuous contact angle changes, automatically batch-fitted by software.

USB 2.0 standard interface ensures fast data transfer, high compatibility, and stable imaging.

One-button multi-point measurement: automatic sample loading → automatic liquid dispensing → automatic measurement → automatic point switching.

Utilizing internationally advanced computational methods, the software achieves fully automated fitting to eliminate human-induced measurement errors.

Software automatically generates reports in multiple formats including Word, Excel, and graphical spectrum formats.

Multiple optional accessories are available. Our robust R&D team can fulfill diverse custom measurement requirements proposed by clients.

Test protocols for different samples can be saved for direct selection during subsequent measurements of corresponding samples.

Sample configuration settings: Measurement protocols can be customized within the software based on actual sample dimensions. For subsequent identical products, stored protocols can be retrieved directly to initiate testing.

Product parameters

| Contact Angle Main Unit | |

| Dimensions | 690mm (L) × 380mm (W) × 680mm (Height) |

| Weight | 43KG |

| Power Supply | 220V / 60Hz |

| Light Source System | |

| Light Source | Dense LED adjustable blue-toned industrial-grade cold light source |

| Lifespan | Service life exceeding 25,000 hours |

| Injection Unit | |

| Syringe | Dedicated high-precision quartz syringe, 500μL capacity |

| Droplet Volume | Software-controlled automatic liquid delivery, precision up to 0.01μL |

| Injection Unit Movement | Software-controlled automatic vertical travel: 60mm; 30mm lateral movement |

| Acquisition System | |

| CCD | Genuine imported SONY high-speed industrial-grade chip, 25 frames/ S, 130W pixels |

| Lens | 0.7-4.5x high-definition industrial-grade continuous zoom microscope |

| Acquisition System Adjustment | 50mm front-to-back (3mm fine adjustment), adjustable viewing angle (for multiple perspectives including level view, downward view, upward view, and 360° rotation) |

| Stage Assembly | |

| Stage Dimensions | 120mm*150mm (customizable based on actual sample size) |

| Maximum Sample Size | 6 inches |

| Stage Movement | Forward/Backward Movement: Automatic, Travel: 200mm, Accuracy: 0.01mm Lateral Movement: Automatic, Travel 200mm, Accuracy 0.01mm Vertical Movement Manual, Travel 30mm, Accuracy 0.01mm |

| Analysis Software | |

| Contact Angle Measurement Range | 0-180° |

| Contact Angle Measurement Accuracy | ±0.1° |

| Interfacial Tension Measurement Range | 0-2000 mN/m |

| Interfacial Tension Measurement Accuracy | 0.01 mN/m |

| Analysis Software Features | 1. China's most advanced contact angle measurement analysis software featuring automatic fitting method (one-click automatic fitting, eliminating manual error) including: ① Circle method fitting; ② Ellipse/Oblique ellipse fitting method; ③ LY method; ④ Differential circle/Differential ellipse method 2. Dynamic contact angle fitting (batch fitting of multiple images) includes: Wettability testing, Video analysis 3. Surface Energy Calculation 4. Surface Tension Measurement 5. Advancing and Receding Angle Measurement 6. Adhesion Work 7. Automatic batch measurement scheme configuration (supports setting test schemes for designated samples and retrieving automated test plans)8. Sample Protocol Configuration: Measurement protocols can be customized within the software based on actual sample dimensions. For subsequent identical products, stored protocols can be directly retrieved to initiate testing 9. One-Click Multi-Point Measurement (with repeat cycles): Auto-sampling → Auto-dispensing → Software-automated measurement → Auto-transition to next measurement point 10. Measurement protocols can be configured and saved for different samples, enabling direct retrieval for subsequent measurements of the same sample type |

+86 19353291814

+86 19353291814