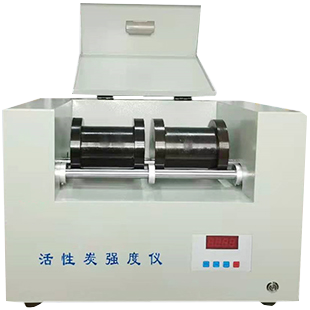

Box-type Atmosphere Furnace

- Product Number:LD-9-12

- Product Difference:Maximum temperature: 1200°C, suitable for high-temperature atmosphere sintering, atmosphere reduction, CVD experiments, vacuum annealing, and other applications

Product Introduction

Our company possesses over 15 years of experience in the high-temperature electric furnace field. Our main products include: chamber furnaces, atmosphere furnaces, tube furnaces, crucible furnaces, lift furnaces, car-bottom furnaces, dental prosthesis furnaces, crystal growth furnaces, vacuum furnaces, graphite furnaces, degassing furnaces, and other high-temperature equipment ranging from 300°C to 3000°C. We also provide various non-standard customizations based on feasible solutions.

Chamber atmosphere furnaces are used in universities, research institutes, and industrial enterprises for high-temperature atmosphere sintering, atmosphere reduction, CVD experiments, vacuum annealing, and more. They feature uniform temperature distribution, rapid heating/cooling rates, energy efficiency, and the capability to introduce multiple gases.

| Model | Furnace Dimensions (D x W x H) | Voltage (V) | Power (kW) | Overall Dimensions (DxWxH) |

| LD-1-12TP | 100*100*100 | 220 | 1 | 430*473*692mm |

| LD-2-12TP | 200*150*150 | 220 | 2 | 570*570*860mm |

| LD-6-12TP | 300*200*200 | 220 | 6 | 740*645*955mm |

| LD-9-12TP | 400*300*300 | 380 | 9 | 805*760*1190mm |

Product Features

The furnace chamber utilizes premium alumina fiber material, offering excellent thermal insulation, durability, high tensile strength, no impurities, high purity, and significant energy savings.

The heating elements employ premium HRE resistance wire, greatly extending their service life.

Features over-temperature alarms and leakage protection for safe and reliable operation.

The furnace shell employs a double-layer forced air cooling design, maintaining the outer shell temperature near room temperature even at maximum operating temperatures, never exceeding 60°C.

The inlet end can be configured with one or multiple air inlets, each equipped with a needle valve and connected to a vacuum gauge. The outlet end connects to one exhaust port and one vacuum port, with all ports fitted with needle valves.

This product is certified to the European Union's CE standard and the ISO 9001:2008 Quality Management System.

Product parameters

| Operating Temperature | 1100℃ |

| Maximum Temperature | 1200℃ |

| Maximum Vacuum | -0.1MPa |

| Sealing Method | 304 Stainless Steel KF Flange |

| Compatible Atmospheres | All Inert Gases, Nitrogen, Argon, Carbon Dioxide, Water Vapor |

| Heating Rate | ≤30℃/ Min |

| Temperature Control Accuracy | ±1℃ |

| Heating Element | Molybdenum-Doped Iron-Chromium-Aluminum Resistance Wire |

| Thermocouple | Type K |

| Operating Voltage | 220V 50Hz |

| Power | 1KW |

| Vacuum Pump | VP125 |

+86 19353291814

+86 19353291814