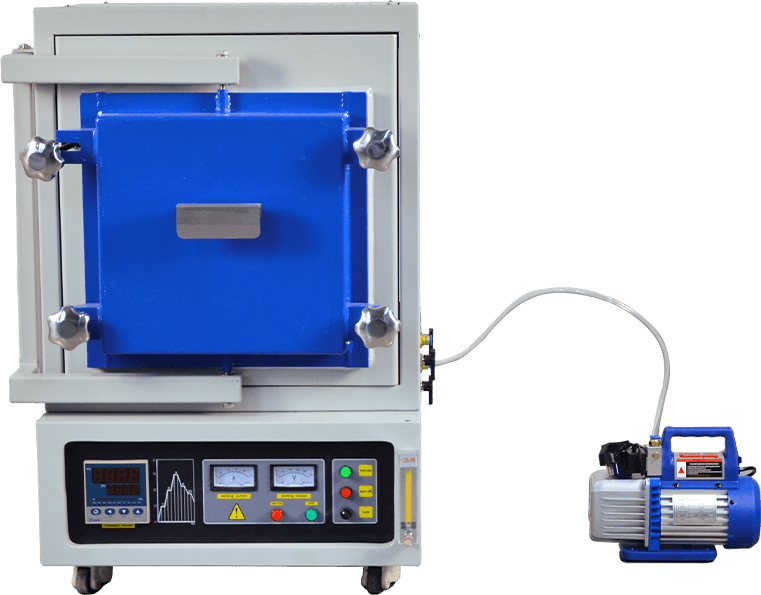

Vacuum Tube Furnace

- Product Number:LD-2-14A

- Product Difference:Maximum temperature: 1400°C, suitable for high-temperature atmosphere sintering, atmosphere reduction, CVD experiments, vacuum annealing, and other applications

Product Introduction

Our company possesses over 15 years of experience in the high-temperature electric furnace field. Our main products include: chamber furnaces, atmosphere furnaces, tube furnaces, crucible furnaces, lift furnaces, car-bottom furnaces, dental prosthesis furnaces, crystal growth furnaces, vacuum furnaces, graphite furnaces, degassing furnaces, and other high-temperature equipment ranging from 300°C to 3000°C. We also provide various non-standard customizations based on feasible solutions.

Vacuum tube furnaces are utilized by universities, research institutes, and industrial enterprises for high-temperature atmosphere sintering, atmosphere reduction, CVD experiments, vacuum annealing, and other applications.

Product Features

The furnace chamber utilizes premium alumina fiber material, offering excellent thermal insulation, durability, high tensile strength, no impurities, high purity, and significant energy savings.

The heating elements employ high-quality HRE resistance wire, greatly extending their service life.

Features over-temperature alarm and leakage protection for safe and reliable operation.

Product parameters

| Maximum Temperature | 1400℃ |

| Typical Operating Temperature | Below 1300℃ |

| Heating Element | Silicon Carbide Rod |

| Heating Method | Double-Sided Heating |

| Thermocouple | Type S |

| Temperature Control Accuracy | ±1℃ |

| Operating Voltage | 220V/8KW |

| Design | The electric furnace features a user-friendly design that is aesthetically pleasing and easy to operate. The outer coating employs a spray-plastic high-temperature baking process, providing resistance to high temperatures, oxidation, and acids/alkalis |

| Shell Design | The furnace shell employs a double-layer forced air cooling structure. This keeps the external shell temperature near room temperature even at high operating temperatures, preventing accidental burns |

| Furnace Chamber Structure | Featuring an integrated, compact design with a stepped joint structure that complies with mechanical principles. This ensures even stress distribution during heating, minimizes heat loss, and extends the furnace chamber's service life |

| Furnace Chamber Material | The chamber utilizes advanced lightweight alumina ceramic fiber, offering superior insulation, lightweight construction, high-temperature resistance, and stability under extreme thermal cycling. It resists cracking, crystallization, and slag shedding, preventing contamination of processed products. Energy efficiency is 60%-80% higher than traditional electric furnaces |

| Temperature Control | Features intelligent temperature control instruments from Yudian Instrument Factory, supporting 30-segment programmable PID self-tuning. One-button operation enables automatic heating and cooling cycles without constant monitoring, ensuring simple and convenient operation |

| Heating Rate | 0–20°C/min freely adjustable, recommended ≤10℃/min |

| Safety Protection | Integrated circuit and modular control (featuring temperature deviation protection, over-temperature protection, thermocouple break protection, overcurrent protection, and other safeguards) ensures stable, reliable, and safe operation of the furnace |

| Compatible Gases | All inert gases, mixed gases, nitrogen, oxygen, carbon monoxide, argon, etc. |

| Gas Control | One inlet port can be configured at the gas inlet end, each equipped with a needle valve and connected to one vacuum gauge. The gas outlet end connects to one exhaust port and one vacuum port. all ports equipped with needle valves, and includes one vacuum pump |

| Sealing Method | Utilizes 304 stainless steel flanges for easy installation/removal, oxidation resistance, acid/alkali resistance, and double-layer sealing to ensure airtightness |

| Warranty Period | One-year warranty on furnace body (excluding heating element wear parts), lifetime maintenance |

| Standard Accessories | One vacuum pump, one crucible hook, one pair of high-temperature resistant gloves, one user manual, certificate of conformity, warranty card |

| Product Certification | This product is certified to EU CE standards and ISO 9001:2015 Quality Management System certification |

| Packaging | Export wooden crate with foam padding inside, furnace body wrapped in plastic film |

| Upgrade Options | Additional cost applies for upgrade to: Yudian Instrument's smart touchscreen temperature controller, featuring 10 sets of 50-segment intelligent programmable PID auto-tuning. One-touch operation, automatic heating and cooling, no need for constant monitoring. Real-time display of temperature curves and data sheets with historical review. Supports data export to USB drives. PC-based operation/ viewing/analysis/printing via PC. Simple and convenient operation with ±1℃ temperature control accuracy. |

+86 19353291814

+86 19353291814