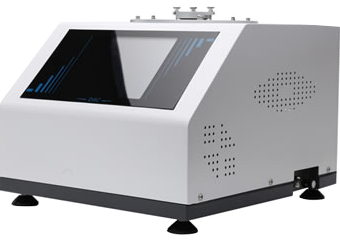

Ultrasonic Hardness Meter

- Product Number:LD-YD900

- Product Difference:Surface hardness testing for various components of all sizes

Product Introduction

The ultrasonic hardness tester features a color display with comprehensive readouts. Nine buttons on the front panel enable various menu settings. A USB port on the side facilitates charging and data communication, with an indicator light beside it showing charging status. This instrument measures surface hardness on both large and small components, including hard-to-reach areas such as tooth flanks or gear roots.

Applications include:

1. Hardness measurement of flange edges, gear root stampings, tooling, sheet metal, surface-hardened teeth and gear grooves, and tapered sections

2. Hardness measurement of shafts, thin-walled pipes, and containers

3. Hardness measurement of wheels and turbine rotors

4. Hardness measurement of drill bit cutting edges

5. Hardness measurement of welded areas

6. Measurement of deep holes with specific bore diameters, indentations/protrusions with significant curvature, and irregular surfaces

7. Hardness measurement covering the vast majority of ferrous metals, non-ferrous metals, and their alloys in industrial production

Product Features

Compact size and lightweight design for easy portability. Enables straightforward online measurement, suitable for field applications and large workpiece inspections. Accessible even in hard-to-reach areas such as tooth flanks or gear roots.

High measurement accuracy: Achieves ±4%HV, ±4%HB, ±1.5HR.

Minimal test indentation: Requires high-power microscope observation, causing negligible damage to workpieces.

Rapid measurement speed: Outputs test results in as little as 1 second.

Large-screen display: Directly shows current measurement values, cumulative measurements, maximum/minimum values, averages, and unit conversion values.

Simple calibration: Stores 5 sets of single-point calibration data, 1 default set, and 5 multi-point calibration sets internally.

Stores 50 sets of measurement data and 10 calibration sets.

Single-point calibration for materials with varying elastic moduli ensures convenience and efficiency.

For materials without clear conversion tables or unknown materials, any hardness scale can be selected for multi-point calibration, eliminating systematic errors caused by conversion tables.

Any hardness scale can be customized in multi-point calibration mode.

Can connect to an external Bluetooth printer to print measurement data (optional) or connect to a computer terminal to export measurement data.

Product parameters

| Measurement Range | HV50-1599, HRC20-68, HB85-650, HRB41-100, HRA61-85.6, HS34.2-97.3, MPa 255-2180 |

| Test Parameters | Vickers HV |

| Conversion Parameters | Rockwell HRC, HRA, HRB; Brinell HBW, etc. |

| Measurement Accuracy | ±4% HB, ±1.5 HR, (Refer to HV Maximum Permissible Relative Error Table) |

| Test Direction | Supports 360° measurement. Measurement possible when indenter forms 90°±3° angle with test surface |

| Data Storage | 50 sets of measurement data and 10 calibration data sets |

| Display Type | Color screen display |

| Battery Specifications | 3.6V, 3000mAh lithium battery |

| Battery life | 10 hours |

Table of Maximum Permissible Relative Errors

| Hardness of the standard block | Maximum Permissible Relative Error of the Hardness Tester % | |||

| HV10 | HV5 | HV2 | HV1 | |

| <250HV | 4 | 4 | 4 | 4 |

| 250HV-500HV | 4 | 4 | 4 | 4 |

| >500HV-800HV | 4 | 4 | 5 | 5 |

| >800HV | 4 | 4 | 6 | 6 |

Probe Parameters

| Probe Type | 1kgf Manual Probe | 2kgf Manual Probe | 3kgf Manual Probe | 5kgf Manual Probe | 10kgf Manual Probe |

| Configuration | Optional | Standard | Optional | Optional | Optional |

| True test force | 10N | 20N | 30N | 50N | 98N |

| Diameter | 22mm | 22mm | 22mm | 22mm | 22mm |

| Length | 150mm | 150mm | 150mm | 150mm | 150mm |

| Resonator rod diameter | 2.4mm | 2.4mm | 2.4mm | 2.4mm | 2.4mm |

| Maximum surface roughness | Ra<3.2μm | Ra<5μm | Ra<5μm | Ra<10μm | Ra<15μm |

| Minimum workpiece weight | 0.3kg | 0.3kg | 0.3kg | 0.3kg | 0.3kg |

| Minimum thickness of workpiece | 2mm | 2mm | 2mm | 2mm | 2mm |

| Probe Applications | Ion nitrided punches, mold shells, fixtures, thin-walled components, bearings, gear flanks, and pipe inner walls | Ion nitrided punches, mold shells, fixtures, thin-walled components, bearings, gear flanks, and pipe inner walls | Ion nitriding for punches, mold shells, fixtures, thin-walled components, bearings, gear flanks, and pipe inner walls | Measuring grooves, gear flanks, and gear roots | Small forgings, cast materials, weld inspection, heat-affected zones, low roughness requirements |

+86 19353291814

+86 19353291814