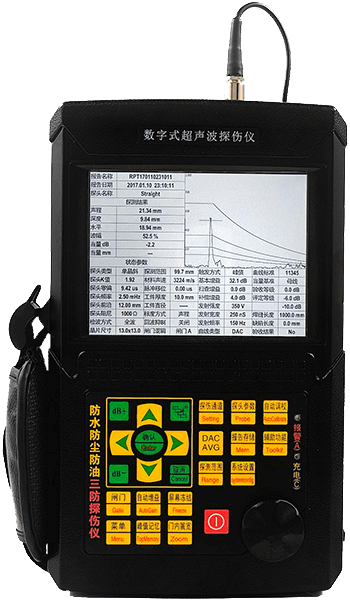

Ultrasonic Flaw Detector

- Product Number:LD-CTS1

- Product Difference:Detection range: 0-6000mm Sound velocity: 1000-10000m/s Supports data export Vertical linear error: ≤4%

Product Introduction

Digital ultrasonic flaw detectors enable convenient and accurate detection, localization, evaluation, and diagnosis of various internal defects in workpieces, such as cracks, welds, porosity, sand holes, inclusions, and folds. They are widely used in power generation, petrochemicals, boiler pressure vessels, steel structures, aerospace, rail transportation, automotive, and machinery industries. This instrument is essential in the non-destructive testing field.

Product Features

Two probe modes: single-crystal and dual-crystal. Automatic probe calibration eliminates manual calculations.

Automatically generates DAC and AVG curves using standard test blocks.

Automatically displays echo-related parameters (depth D, horizontal P, distance S, amplitude H).

16 flaw detection channels, allowing free input and storage of industry-specific flaw detection standards.

Capable of storing 980 A-scan images.

Four weld type diagram functions (I, V, U, X) for intuitive reflection location identification.

Automatic calculation of defect equivalent φ value.

High sampling rate with low noise.

Echo suppression function with warning light indication.

Supporting functions: gate-activated audible/visual alarms, automatic gain control for enhanced inspection efficiency, dual input modes for probe angle and K-value, peak memory and echo envelope for rapid identification of maximum echoes, USB interface for PC data transfer and automatic inspection report generation.

Intuitive keypad for simplified operation. Large high-brightness display meets inspection requirements in sunlight and culverts.

Product parameters

| Scanning Range (mm) | 0~6000 |

| Vertical Linearity Error | ≦4% |

| Horizontal Linearity Error | ≦0.1% |

| Flaw Detection Sensitivity Reserve | ≧60dB (for 200mm deep φ2 flat-bottomed holes) |

| Dynamic Range | ≧32dB |

| Resolution | ≧34dB |

| Frequency Range (MHz) | 0.5~20 |

| Gain Adjustment (dB) | 0~110 |

| Material Sound Velocity (m/s) | 1000~9999 |

| Echo Suppression | 0~80% |

| Operating Temperature (℃) | -27 to 70 |

| Dimensions (mm) | 240*160*40 |

| Weight (Kg) | 1.3 |

| Optional Accessories | Probe, Standard Test Block, Laptop computer, PC communication software, BNC cable |

+86 19353291814

+86 19353291814