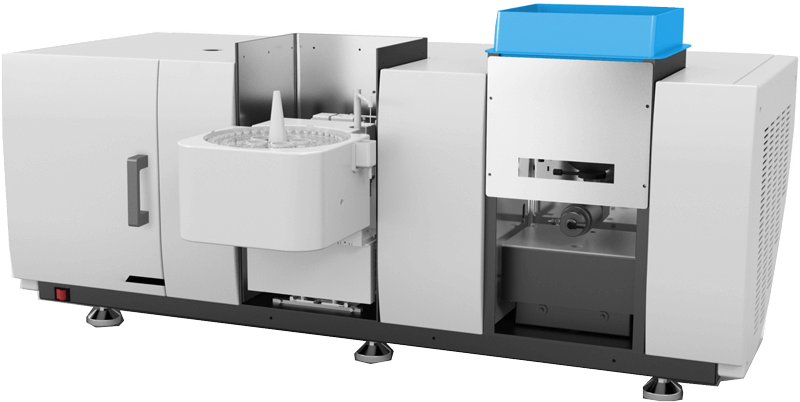

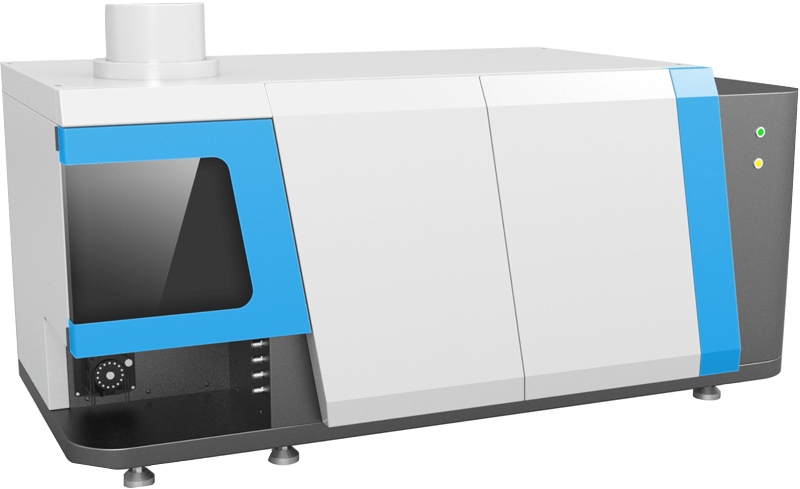

ICP Spectrometer

- Product Number:LD-ICP1 Petrochemical

- Product Difference:5–10 elements/min, primarily used for determining the elemental content in various petroleum products and related derivatives

Product Introduction

The LD-ICP1 (Petrochemical) Single-Channel Scanning Inductively Coupled Plasma Emission Spectrometer is a specialized chemical analysis instrument meticulously designed to meet the testing requirements of the petrochemical industry. It is primarily used to determine the elemental content in various petroleum products and related derivatives.

The ICP spectrometer innovatively employs direct oil sample injection technology. Its semiconductor-cooled cryogenic nebulizer, combined with oxygen-assisted injection, eliminates severe carbon buildup in organic samples, significantly enhancing the instrument's applicability.

Applications include:

1. Direct injection analysis of gasoline and diesel without complex digestion procedures, enabling determination of elements such as silicon, phosphorus, iron, manganese, and lead.

2. Measures over twenty wear elements in lubricants and their additives, requiring only simple dilution before testing.

3. Optional high-salt atomizer enables direct determination of wear elements in used lubricants.

4. Analyzes over thirty elements in crude oil and its byproducts.

5. Determines elemental content in petrochemical feedstocks like methanol and ethanol.

6. Elements including sodium, potassium, calcium, magnesium, aluminum, iron, nickel, copper, zinc, and chromium in automotive urea.

7. Determination of rare earth elements in oilfield tracers.

Product Features

High-Precision Gas Flow Control System

All plasma gas, auxiliary gas, carrier gas, and oxygen used during instrument operation are controlled by high-precision mass flow controllers (MFCs). These controllers enable continuous flow adjustment and deliver highly accurate output gas flow, ensuring the accuracy of test data.Safe and Reliable Solid-State RF Power Supply

The RF power supply features a compact design, high output efficiency, and stable power delivery. It incorporates comprehensive safety protections including water circuit, gas circuit, and overload safeguards, significantly enhancing instrument safety and reducing failure rates.High-Precision Temperature Control System

The entire optical path is protected by a precision temperature control system. Temperature settings can be adjusted in real-time based on the actual ambient temperature in the customer's laboratory, eliminating the need for continuous operation. Temperature control accuracy is ≤±0.1℃. This precise temperature control system ensures optical path stability and more reliable test data.Ultra-low operating costs

When the instrument is inactive, the power supply, cooling water tank, and gas supply are all shut off, incurring no operational expenses. The instrument is ready for immediate use upon activation, eliminating the need for prolonged optical path warm-up. It operates effectively with argon gas purity of 99.99%, eliminating the requirement for ultra-high-purity 99.999% argon, resulting in cost savings of at least one-third.High Instrument Automation

Except for the power switch, all operations are performed by software. The intelligent software provides real-time feedback and prompts for each operation.Peristaltic Pump Injection System

The instrument features a high-precision, four-channel, twelve-roller peristaltic pump. This design simultaneously ensures injection accuracy and prevents liquid accumulation. The pump's speed is continuously adjustable to meet diverse testing requirements.Fully Automatic Ignition and Matching Technology

The software enables fully automatic one-touch ignition, with all parameter adjustments completed automatically. Combined with advanced automatic matching technology, it achieves high ignition success rates and simplified operation.Intelligent Flame Monitoring Function

The instrument features a highly sensitive fiber optic sensor that continuously monitors flame status during operation. In case of abnormal flame extinction, the instrument automatically shuts down.High-Performance Dedicated Sample Introduction System

Addressing the high volatility of petroleum products, the system incorporates a proprietary refrigeration system that cools samples to -20°C before introduction. This ensures sample stability, enhances atomization efficiency, and delivers more stable and accurate test results.Automatic observation position adjustment

The instrument employs a two-dimensional moving platform design. The torch tube position can be adjusted in real time via software, using feedback signal values to locate the optimal observation position. This ensures high sensitivity and accurate test results.Ultra-High Resolution Optical Path System

The instrument incorporates an imported 4320-line ultra-high resolution grating. Combined with optical path adjustment technology, it reduces the resolution from approximately 0.008nm in conventional instruments to below 0.005nm. This high resolution ensures no interference between tested elements.High-Sensitivity Detector

The instrument features a high-sensitivity imported photomultiplier tube (PMT) as the detector. It automatically configures test parameters for different target elements to achieve optimal detection conditions and deliver precise results. No cooling or purging is required, and it offers a long service life.Exceptional Testing Speed

Capable of analyzing over 70 elements simultaneously. Fast analysis rate of approximately 5 elements per minute, with a maximum speed of 10 elements per minute.Highly sensitive detection technology

Low detection limits, reaching ppb levels for most elements; wide linear range spanning 5-6 orders of magnitude, enabling simultaneous testing of high and low concentrations without changing calibration curves; oil samples require no digestion and can be tested directly after simple preparation.

Product parameters

| Solid-State Power Supply | Operating Frequency | 27.12MHz, Frequency Stability < 0.05% |

| Matching Method | Automatic Matching | |

| Power | Output Power 800W to 1600W, continuously adjustable, power supply efficiency >65%, output power stability ≤0.05% | |

| Output Working Coil | Inner diameter 25mm, 3 turns, paired with a triple-concentric quartz torch tube with outer diameter 20mm | |

| Coaxial Sprayer | Outer diameter 6mm, Swirl atomization chamber | |

| Sample introduction system | Direct injection system for organic samples, cooling temperature down to -20°C | |

| Scanning Spectrometer | Optical Path | Czerny-Turner Type |

| Focal Length | 1000mm | |

| Grating Specifications | Ion-Etched Holographic Grating, line density 3600 L/mm or 2400 L/mm | |

| Engraving area | (80 ×110)mm | |

| Resolution | ≤0.015nm (2400 line grating) | |

| Scanning Wavelength Range | 2400 line grating (190–800) nm | |

| Electronic Measurement and Control Circuitry | Photomultiplier Tube Specifications | R212/R928 |

| Photomultiplier Tube Negative Voltage | (-50 to -1000) V | |

| Photomultiplier Tube Current Measurement Range | (10⁻¹² to 10⁻⁴) A | |

| Signal Acquisition | VF Conversion | |

| Computer System | Host: Brand-name computer, Monitor: 17-inch LCD display, Printer: Brand-name printer | |

+86 19353291814

+86 19353291814