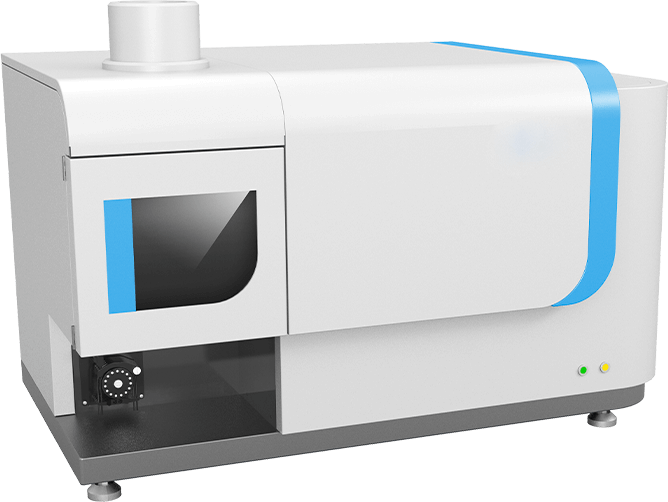

Atomic Absorption Spectrometer

- Product Number:LD-AAS3

- Product Difference:Features multiple atomization methods including flame, graphite furnace, and hydride generation

Product Introduction

The Flame-Graphite Furnace Integrated Atomic Absorption Spectrometer is a high-performance, highly reliable spectroscopic instrument developed, manufactured, and sold independently by our company. It incorporates years of spectral research and development expertise and offers multiple atomization methods, including flame, graphite furnace, and hydride generation.

Product Features

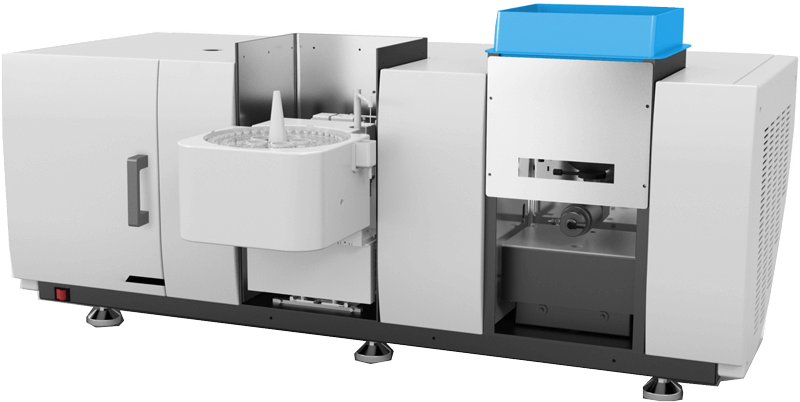

Integrated design featuring a serial optical path configuration. The flame graphite furnace atomizer remains fixed in position, with software-automated switching eliminating the need for hardware replacement. Switching occurs in one second, preventing errors caused by mechanical switching while enhancing instrument stability and maintainability.

Comprehensive and powerful analytical software. User-friendly interface for effortless operation. Supports switchable Chinese/English Windows-style software interface, compatible with Windows XP, Windows 7, and other operating systems.

Background correction system with dual switching between element lamp and deuterium lamp plus background subtraction. Features two background correction modes: deuterium lamp and self-absorption. Achieves over 50 times background subtraction capability at a background signal of 1A.

Fully retracted achromatic optical system employs concave mirrors instead of convex lenses for optical focusing, effectively resolving chromatic aberration issues caused by differing focal lengths of various elements and enhancing optical system efficiency.

Eight-element lamp tower allows one lamp to operate while up to seven others preheat simultaneously, saving lamp replacement and preheating time for faster, more convenient element measurement.

Fully automated design: All instrument functions are monitored and controlled via computer except the main power switch. The software automatically determines optimal testing conditions for each element.

USB 3.0 communication: Industry-leading adoption of USB 3.0 interface enhances communication speed and ensures compatibility with computer systems.

C-T monochromator employs a 1800 lines/mm grating with a blazing wavelength of 230nm for the spectroscopic system.

Streamlined sheet metal construction delivers a sleek, modern aesthetic.

Fully automated qualitative and quantitative analysis, automatically calculates elemental content, and generates test reports.

Flame System

(1) High-efficiency glass atomizer: Utilizes a specialized high-efficiency glass atomizer for superior atomization efficiency and easy maintenance/replacement.

(2) Pure titanium atomization chamber and combustion head effectively prevent acid gas corrosion, extending service life.

(3) Mass flow controller (MFC) precisely regulates acetylene flow with accuracy down to 1 ml/min, while dynamically monitoring flow for user-friendly, safe, and reliable operation.

(4) Enhanced safety protections ensure secure and reliable sample analysis: ① Acetylene leak detection, ② Acetylene pressure monitoring, ③ Air pressure monitoring, ④ Burner head status monitoring, ⑤ Flame status monitoring, ⑥ Water seal status monitoring.Graphite Furnace System

(1) Integrated design houses both the graphite furnace power supply and atomic absorption main unit within a single instrument. This reduces cable length, minimizes electromagnetic interference from the graphite furnace power supply, and enhances graphite tube heating efficiency.

(2) Enhanced safety protections ensure more secure and reliable sample analysis: ① Cooling water flow monitoring, ② Carrier gas pressure monitoring, ③ Graphite tube temperature monitoring, ④ Graphite furnace temperature monitoring.

(3) High-precision graphite furnace temperature control with rapid heating rates. Utilizes a high-power transformer, low-resistance cables, and light-controlled heating, complemented by software and hardware temperature calibration systems. Achieves ±1% temperature accuracy in the high-temperature range.

(4) 150-position rotary graphite furnace autosampler. Polar coordinate rotary graphite furnace autosampler enables shared autosampler use for both flame and graphite furnace modes. Features high positioning accuracy, stable and reliable operation, and convenient maintenance.

(5) Automatic carrier gas flow control. Both internal and external gases within the graphite furnace are automatically regulated by the computer according to the software-programmed heating profile.

Product parameters

| Flame System | Precision | < 0.8% (Copper by Flame Method) |

| Detection Limit | < 0.008 μg/mL | |

| Characteristic Concentration | < 0.025 μg/mL/1% (flame method for copper) | |

| Static Stability | 0.003 Abs (static) | |

| Dynamic Stability | 0.004 Abs (dynamic) | |

| Graphite Furnace System | Temperature Control Range | Room Temperature--3000℃ |

| Heating Rate | 3000℃/s | |

| Graphite Furnace Cadmium (Cd) Analysis | Precision: ≤ 2%, Characteristic Amount: ≤ 0.5pg, Detection Limit: ≤ 1pg | |

| Monarch Type | Czerny-Turner (CT) | |

| Wavelength Range | 190nm~900nm | |

| Wavelength Accuracy | ±0.25nm | |

| Wavelength Repeatability | < 0.05nm | |

| Spectral Bandwidth | 0.1/0.2/0.4/0.7/1.4 nm (Five-Band Auto Switching) | |

| Power Supply | 220V±22V, 50Hz±1Hz, 5kW (peak) | |

+86 19353291814

+86 19353291814