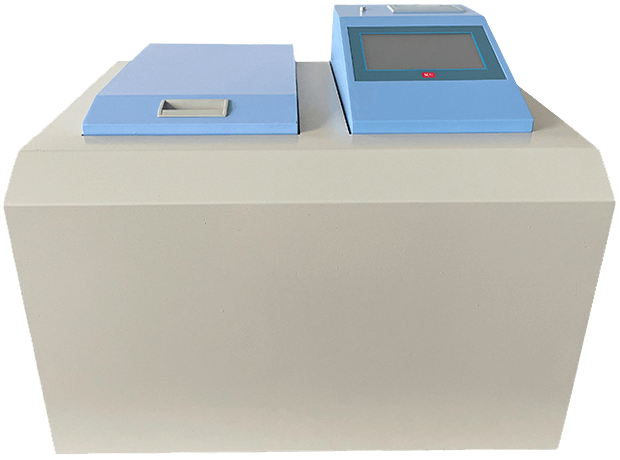

Liquefied Petroleum Gas Analyzer

- Product Number:LD-R1 Liquefied Petroleum Gas Configuration 1

- Product Difference:Connect to computer, detect primary components

Product Introduction

Liquefied Petroleum Gas Analyzer Developed to meet the practical application needs of a wide range of users, this domestically produced fully automated gas analyzer integrates an automatic gas generation system with an analysis system. It features an organic combination of sample valves and computer-controlled data acquisition, offering a simple structure and convenient operation.

Suitable for: LPG/LNG/CNG filling stations, oilfield gas, coalbed methane, mine gas, shale gas, gas pipeline transportation companies, gas transportation companies, gas storage facilities, coal-to-gas conversion enterprises, LNG point-of-use supply, gas appliance manufacturers, petroleum refining, coking plants, smelting plants, and gas supply stations.

Applicable to the following ranges:

1. Content of additives in liquefied petroleum gas (LPG), including dimethyl ether, methanol, carbon monoxide, nitrogen, etc.

2. Gas components in liquefied petroleum gas (LPG), natural gas, coal gas, etc.

3. Dimethyl ether purity

4. Nitrogen, carbon dioxide, methane, ethane, ethylene, propane, propylene, dimethyl ether, isobutane, n-isobutylene, n-butane, isobutylene, cis-butylene, isopentane, n-pentane, etc. in liquefied gas

5. Component content, calorific value, density, White's number, methane, nitrogen, carbon dioxide, propane, ethane, n-butane, n-pentane, isopentane, and C6+ hydrocarbon components; higher heating value, lower heating value, density, relative density, White's number, combustion potential, etc.

Product Features

Seamlessly integrates a high-purity hydrogen generator with an analyzer, enabling precise analysis of gas content through a single sample injection.

The workstation features intuitive operation—a single press of the remote control button initiates the entire process from spectrum acquisition to printing analytical reports.

Equipped with a built-in dual-channel dedicated workstation, the software features a multi-document interface allowing simultaneous opening of multiple document windows. Each window corresponds to an independent sampling channel and operates completely autonomously. Utilizing split-window technology, tables and spectra are displayed within the same document window, with the spectrum display area size freely adjustable.

Highly integrated electronic circuitry ensures excellent reliability and straightforward operation, guaranteeing stable and dependable instrument performance. This enhances work efficiency while reducing maintenance costs. Automatic parameter memory eliminates the need for resetting upon startup.

The gas delivery system employs a high-precision valve structure, significantly improving gas flow stability and delivering analytical results with excellent reproducibility.

Product parameters

| Column oven temperature | Room temperature +5–200°C, accuracy ±0.1°C, carrier gas: High-purity hydrogen (Purity ≥99.995%) |

| Thermal Conductivity Detector (TCD) | Sensitivity s ≥3000 mV·ml/mg (benzene), Noise ≤0.02 mV |

| Qualitative Time Error | ≤0.02 min |

| Quantitative repeatability | RSD ≤ 1% |

| Instrument dimensions | 540 × 390 × 360 (L × W × H mm) |

| Input power | AC 220 V |

+86 19353291814

+86 19353291814