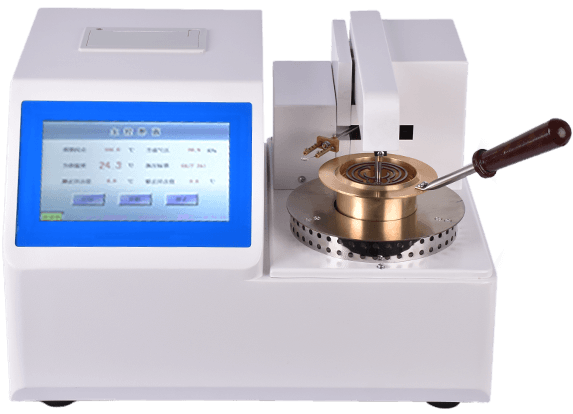

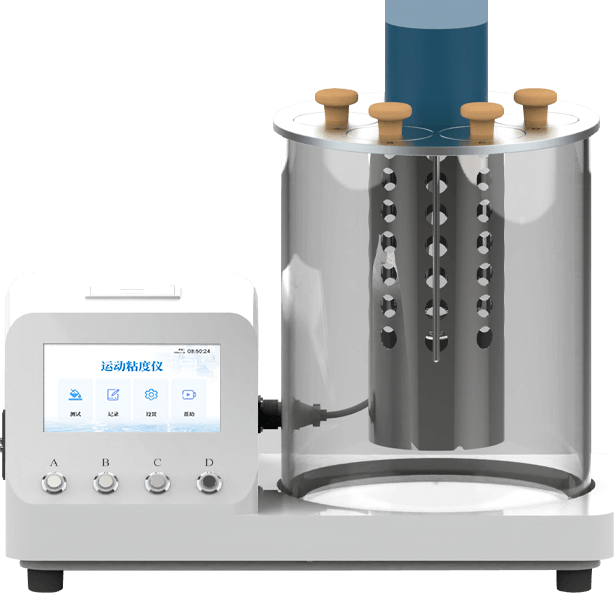

Kinematic Viscosity Meter

- Product Number:LD-YN1

- Product Difference:7-inch color LCD touchscreen display for determining the kinematic viscosity of liquid petroleum products

Product Introduction

The Petroleum Product Kinematic Viscosity Tester is a specialized testing instrument designed and manufactured in accordance with the national standard GB265-88 “Method for Determining Kinematic Viscosity of Petroleum Products.” It is suitable for measuring the kinematic viscosity of liquid petroleum products.

This instrument measures the time taken for the sample to flow and automatically calculates the final kinematic viscosity result. This method is applicable for determining the kinematic viscosity of liquid petroleum products (Newtonian liquids), expressed in m²/s, though commonly used in practice as mm²/s.

Dynamic viscosity can be obtained by multiplying the measured kinematic viscosity by the liquid's density. This method determines the time taken for a fixed volume of liquid to flow under gravity through a calibrated glass capillary viscometer (Parshall or Ubbelohde) at a constant temperature. The product of the viscometer's capillary constant and the flow time represents the kinematic viscosity of the liquid at that temperature. The product of the kinematic viscosity at that temperature and the liquid's density at the same temperature yields the dynamic viscosity at that temperature.

Applicable fields:

1. Chemical Industry

① Solvents: Organic solvents, inorganic solvents, etc. ② Polymer solutions: Polyvinyl alcohol, polyacrylamide, etc.

2. Pharmaceutical Industry

① Pharmaceutical preparations: Ointments, oral liquids, injections, etc.

3. Food Industry

① Food additives: Thickeners, stabilizers, etc. ② Beverages: fruit juices, carbonated drinks, dairy products, etc. ③ Syrups: corn syrup, high-fructose corn syrup, etc.

4. Printing Industry

① Inks: water-based inks, solvent-based inks, etc. ② Adhesives: printing adhesives, bonding agents, etc.

5. Textile Industry

① Dyes: textile dyes, printing pastes, etc.

6. Cosmetics Industry

① Skincare products: Face creams, lotions, serums, etc. ② Hair and body care: Shampoos, body washes, etc.

7. Research Institutions

① Fundamental research: Studies on liquid physical properties. ② New materials: Novel polymers, nanomaterials, etc.

Product Features

7-inch color LCD touchscreen display for convenient operation and enhanced productivity.

Simple operation and precise measurement, designed and manufactured to national standards.

Single-point or multi-point calibration allows selection of the appropriate calibration mode based on usage scenarios.

Fully automatic storage of test results with an embedded thermal printer for convenient printing.

High-precision temperature control technology and high-performance MCU control.

Product parameters

| Test Method | Pins and Wuller methods |

| Temperature Range | Room temperature to +150°C, accuracy ±0.01°C |

| Temperature Sensor | German Class A Pt100 stainless steel probe, built-in temperature correction, reliable detection results |

| Heating Method | Electric heating unit, maximum heating power 1600W |

| Display | 7-inch industrial color touchscreen |

| Temperature Calibration | Single-point calibration, multi-point calibration available |

| Data Storage | 10,000 sets of test results |

| Dimensions | 530*310*232.5 (mm) |

| Operating Environment | ① Temperature: 10-35°C, ② Humidity: Relative humidity ≤50%, ③ Operating Voltage: 220V 50Hz |

+86 19353291814

+86 19353291814