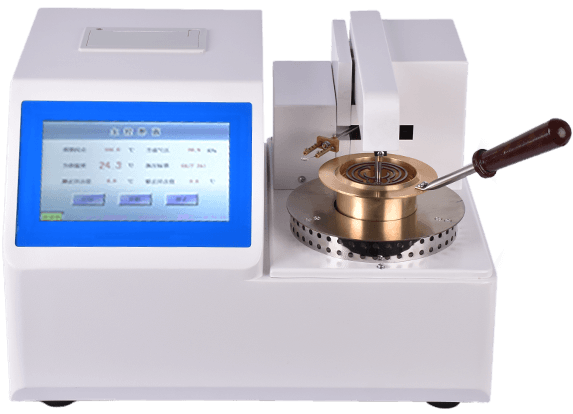

Fully Automatic Open Cup Flash Point Testing Equipment

- Product Number:LD-KS1

- Product Difference:Two-wire PT100, no cold junction compensation, no temperature curve, no auto-lock function

Product Introduction

Fully Automatic Open Cup Flash Point Testing Equipment, designed to determine the open cup flash point and ignition point of petroleum products. The instrument employs an electric ignition method, eliminating the need for any combustible gases, and fully complies with the requirements of ASTM D92 (GB3536-2008) and GB267-88. Featuring an ARM series high-performance microprocessor, EEPROM (capable of storing tens of thousands of data records), color LCD display with touchscreen, and PID self-tuning technology.

The instrument offers the following characteristics: Versatile functionality, capable of simultaneously testing flash point and ignition point with one device, printing test results, and featuring an internal clock chip that automatically displays the current date and time with power-off retention. High precision: Temperature error controlled within ±1.5°C, with 0.1°C resolution. Excellent repeatability: When test conditions comply with GB3536 (ASTM D92) or GB/T 267-88, consecutive tests on the same sample yield flash point values differing by ≤4°C. High automation: Automatically completes the testing process, performs cooling, and provides automated information prompts.

The Open Cup Flash Point Tester aligns with the highest functional and performance standards globally, serving as a specialized instrument for petroleum, power, chemical, and commodity inspection industries to replace imported products.

Product Features

The display features a genuine imported 7.0-inch true-color TFT-LCD screen, while the keyboard employs a human-sensing touchscreen. With a fully Chinese-language interface, it offers a refined, intuitive, and elegant display, ensuring convenient operation and effortless touch control.

Historical data is stored in NVM memory, capable of retaining 20,000 data points. Data remains preserved for 10 years without loss and cannot be altered.

The printer utilizes a miniature embedded thermal printer, ensuring quieter, faster, and clearer printing.

Temperature measurement and control utilize an original imported PT100 platinum resistance temperature sensor, high-precision AD converter, excellent linearization mathematical model, and unique control algorithm, enabling faster, more accurate, and stable temperature measurement and control.

Ignition employs electronic flame direct ignition, identical to gas flame ignition, ensuring safety, convenience, speed, reliability, and interference-free operation.

Flashback detection utilizes high-frequency ion ring flame detection technology, enabling instantaneous and accurate capture of sample flashbacks to prevent false positives and false negatives.

Atmospheric pressure measurement utilizes a fully digital atmospheric pressure sensor imported from Germany, providing real-time measurement of local atmospheric pressure and automatically correcting the impact of atmospheric pressure changes on measurement data.

Automatically completes operations including heating, detection, calculation, and printing.

Product parameters

| Measurement Range | Room Temperature ~ 400°C |

| Temperature Detection | Platinum Resistance Thermometer |

| Sensitivity | 0.1°C |

| Repeatability | Complies with GB3536-2008 (ASTM D92), GB/T 267-88 |

| Display | 7-inch color LCD touchscreen |

| Data Storage | Capacity for 20,000 test results |

| Ignition Method | Electrical ignition |

| Cooling Method | Forced Air Cooling |

| Printer | Chinese Character Display, 40 Lines |

| Self-Diagnostic Function | Lifting Bar, Scanning Bar, Printing, etc. |

| Power Supply | AC 220V ±11V, Frequency 50Hz±2.5Hz |

| Power Consumption | ≤600VA |

| Ambient Temperature | 10~35℃ |

+86 19353291814

+86 19353291814