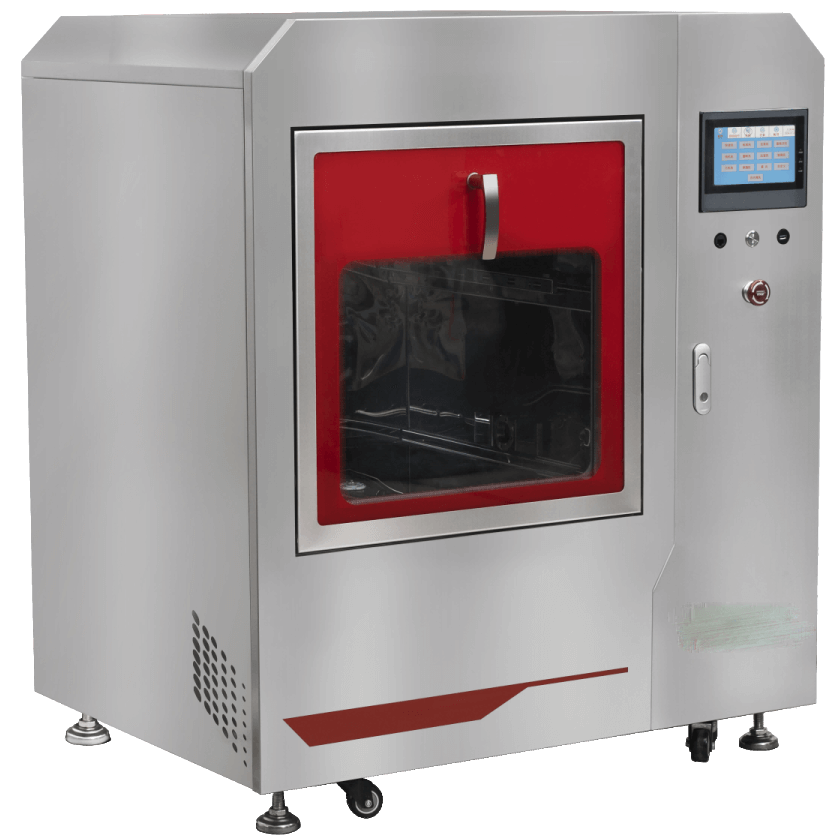

Fully Automatic Bottle Washer

- Product Number:LD-200

- Product Difference:Cleaning and drying of sample vials, test tubes, beakers, pipettes, conical flasks, volumetric flasks, and other laboratory vessels

Product Introduction

Fully automatic bottle washers are suitable for cleaning and drying laboratory vessels such as sample bottles, test tubes, beakers, pipettes, conical flasks, and volumetric flasks in various laboratories including pharmaceutical companies, research institutes, environmental protection agencies, water systems, hospitals, petrochemical systems, and power systems.

Significance of Automated Cleaning

1. Standardized cleaning processes ensure consistent results and minimize uncertainties from manual operation.

2. Facilitates verification and record retention for traceability management.

3. Reduces occupational risks by preventing injuries or infections during manual cleaning.

4. Fully automated washing, disinfection, and drying minimize equipment and labor requirements, delivering cost savings.

Product Features

TWINS Cleaning and Drying System enables in-situ cleaning and drying of laboratoryware.

Material: Cleaning chamber: SUS316L, Outer shell: SUS304.

High Cleanliness

1. European-imported high-efficiency circulation pump ensures stable and reliable cleaning pressure.

2. Cleaning positions arranged based on fluid dynamics principles guarantee thorough cleanliness for every item.

3. Optimized flat-nozzle rotating spray arms ensure 360° coverage with no blind spots.

4. Angled cutouts on the washing column sides ensure 360° coverage of vessel inner walls.

5. Height-adjustable racks guarantee effective cleaning for vessels of varying sizes.

6. Dual water temperature control maintains consistent washing water temperature throughout.

7. Cleaning solution can be preset and automatically replenished.High-Efficiency Drying

1. In-situ drying system.

2. Built-in HEPA high-efficiency filter ensures cleanliness of drying air.

3. Synchronized drying water circulation pipeline prevents moisture contamination of the cleaning system.

4. Dual temperature control ensures precise drying temperature.Operational Management

1. PLC (Programmable Logic Controller) control system ensures stable and reliable operation.

2. Cleaning programs can be freely combined as needed.

3. 7-inch color LCD touchscreen displays all equipment operation information in text format.

4. Three-level password management accommodates different access permissions.

5. Equipment fault self-diagnosis with audible and text alerts.

6. Automatic cleaning data storage function (optional).

7. USB cleaning data export function (optional).

8. Micro printer data printing function (optional).Protection Features

1. Two-point electronic door lock prevents unauthorized access.

2. Dual temperature protection for water and ambient temperatures.

3. Automatic high-temperature protection for circulation pump.

4. Power failure protection function.

5. Drain pipe water seal design prevents sewage backflow.Cleaning Programs

1. Standard Program: Suitable for cleaning generally soiled instruments.

2. Rapid Cleaning Program: Designed for lightly soiled instruments.

3. Custom Cleaning Program: Users can create customized cleaning combinations based on specific requirements.

4. Self-Cleaning Program: Periodically cleans residual scale from circulation lines and internal chambers.

5. Drying Program: Equipped with a high-performance drying system for rapid drying of various instruments.

6. Manual Test Program: Enables users to collect water samples for cleaning efficacy verification and self-check equipment component operation.

Product parameters

| Model | LD-200 | Effective Volume (L) | 200 |

| External Dimensions (W*D*H) mm | 980*740*1080 | Inner Chamber Dimensions (W*D*H) mm | 600*629*635 |

| Voltage (V/Hz) | 220/50-60 | Water Circulation Flow Rate (L/min) | 800 (European Import) |

| Water Heating Power (KW) | 5 | Dry Operation Power (KW) | 2.1 |

| Maximum Operating Power (KW) | 6 | Water Consumption/Cycle (L) | 15 |

| Noise Level (dBa) | < 50 | Inlet Water Pressure (MPa) | 0.3-1.0 |

+86 19353291814

+86 19353291814