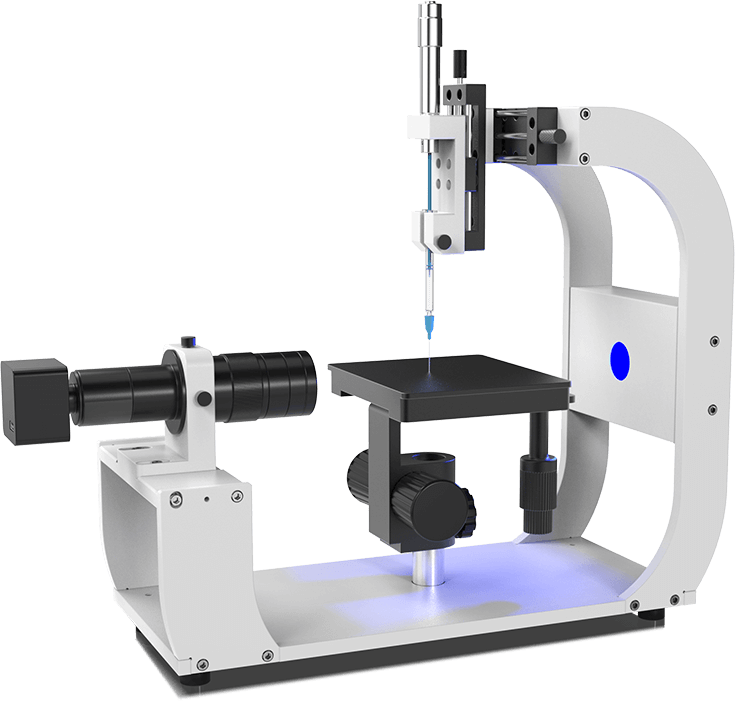

Water Drop Contact Angle Measuring Instrument

- Product Number:LD-JC1

- Product Difference:Standard model, an instrument for measuring the contact angle between liquids and solid materials

Product Introduction

A contact angle measuring instrument is a device used to measure the contact angle between a liquid and a solid material. It is primarily employed to characterize the wetting properties of liquids on solid surfaces. By capturing images of the droplet through optical imaging, computer software utilizes mathematical models to fit the droplet's contour, thereby determining the contact angle or surface tension. This process enables surface energy calculations and wettability analysis.

Water contact angle meters find extensive applications across various fields including materials research, industrial coatings, mobile phone manufacturing, biopharmaceuticals, electronic circuits, textile fibers, petroleum extraction, and aerospace.

Standards (partial list):

① JJF 2099-2024 Calibration Specification for Optical Contact Angle Meters

② GBT 30693-2014 Measurement of Contact Angle Between Plastic Films and Water

③ GBT 30447-2013 Method for Contact Angle Measurement of Nanoscale Films

④ GBT 42694-2023 Textiles - Determination and Evaluation of Surface Anti-Wetting Properties - Contact Angle and Rolling Angle Method

⑤ ASTM D 724-1999 (2003) Standard Test Method for Surface Wettability of Paper (Contact Angle Method)

Product Features

High precision and wide measurement range, supporting contact angle measurement and surface/interfacial tension measurement.

Multi-functional analysis modules and algorithms, multi-mode measurement methods; surface energy and wettability analysis.

Features a dense LED cold light design for uniform illumination, clear imaging, and extended lifespan.

Incorporates a three-dimensional manual precision adjustment stage for flexible operation and accurate positioning; the stage can be customized to accommodate actual sample dimensions.

High-definition imaging system: High-definition industrial camera with a continuous zoom telecentric lens ensures stable capture and sharp images.

Powerful analysis software: Features one-click fully automatic fitting capabilities and fitting methods to precisely fit various droplet morphologies.

Database management: Centralized storage and management of historical measurement data including contact angle, surface tension, and surface free energy. Data remains intact during power loss. Supports real-time data viewing, loading for analysis and comparison, and re-exporting.

Product parameters

| Contact Angle Analysis | Measurement Range | 0~180° |

| Accuracy | ±0.1° | |

| Resolution | 0.001° | |

| Measurement Mode | Automatic measurement, manual measurement, dynamic measurement | |

| Fitting Methods | Width-height method, circular fitting, elliptical fitting, polynomial fitting, Young-Laplace fitting, ADSA-NA fitting | |

| Surface Tension Analysis | Measurement Range | 0.01~2000 mN/m |

| Resolution | 0.001 mN/m | |

| Measurement Method | Suspended Drop Method (Young-Laplace Fitting Method) | |

| Wetting Analysis | Adhesion Work, Spreading Coefficient, and Adhesion Tension | |

| Surface Energy Measurement Methods | Fowkes, OWRK, Wu, Zisman, EOS | |

| Data Management | 1. Test data can be annotated on images and saved alongside them. 2. Test results can be exported to PDF or Excel. 3. Data is not lost during power outages. Supports viewing and loading data for analysis and comparison at any time, and data can be exported again. | |

| Image Capture | Single shot, continuous shooting, video recording, and image playback | |

| System Adjustment | System level testing/ Adjustment | |

| Stage Dimensions | (152×132) mm | |

| Stage Adjustment | Manual knob control for 3D positioning, travel range (X75×Y45×Z50) mm | |

| Camera Resolution | 5.0MP | |

| Maximum Image Size | 2592×1944 | |

| Maximum Frame Rate | 30fps | |

| Focal Length | 100±5mm | |

| Magnification Range | 0.6-4.5x | |

| Light Source | LED cold light source, 470nm | |

| Dropping Method | Straight-in precision micro syringe, manually controlled | |

| Dropping Accuracy | 0.1μL | |

| Syringe | High-precision airtight syringe, 1ml capacity | |

| Needle | 0.52mm stainless steel superhydrophobic needle | |

| Transfer | USB 2.0 | |

| Power Supply | 220V | |

| Dimensions | 545mm (L) × 186mm (W) × 490mm (H) | |

| Main Unit Weight | <8kg | |

+86 19353291814

+86 19353291814