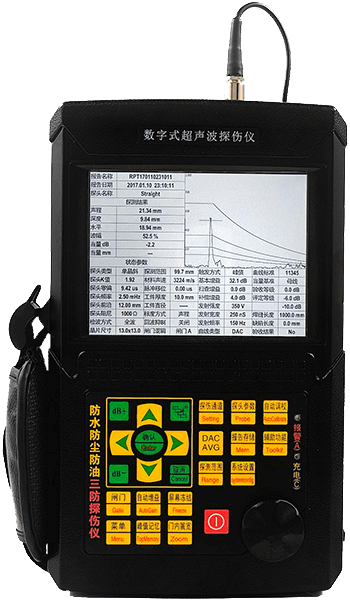

Digital Ultrasonic Fracture Tester

- Product Number:LD-CTS4

- Product Difference:Detection range: 0-10000mm Sound velocity: 500-18000m/s Supports data export Vertical linear error: ≤2%

Product Introduction

The Digital Ultrasonic Fracture Tester is a portable industrial non-destructive testing instrument capable of conveniently, non-destructively, and accurately detecting, locating, evaluating, and diagnosing various internal defects (such as cracks, porosity, inclusions, and laminations) in workpieces. It can be used both in laboratories and on-site in engineering environments. Applications span industries including boilers, pressure vessels, aerospace, power generation, petroleum, chemical processing, offshore oil, pipelines, shipbuilding, automotive, machinery manufacturing, metallurgy, metal fabrication, steel structures, rail transportation, nuclear power, and higher education institutions.

Product Features

Master-slave menu system with quick-access keys and a digital flywheel knob for intuitive operation.

Full-color digital LCD display with customizable background and waveform colors based on environment, featuring freely adjustable brightness.

Compact and portable design fits comfortably in one hand, built for durability and setting industry trends.

Automatically generates DAC and AVG curves using standard test blocks, with unlimited sampling points and support for compensation and correction.

Automatically displays echo-related parameters (Depth D, Horizontal P, Distance S, Amplitude H).

Seamlessly switch between three scales (Depth D, Horizontal P, Distance S).

100 flaw detection channels with freely input and storable industry-specific flaw detection standards (expandable).

Stores up to 300 A-scans and parameters (expandable per user requirements).

Automatically calculates defect equivalent φ values with peak memory function.

Two detection modes: Peak and Edge.

Three probe modes: Single crystal, Dual crystal, Penetration.

Automatic damping matching, intelligent operation for rapid flaw detection, automatic gate alarm; generates custom inspection procedures based on actual workpieces, eliminating the need for test blocks during on-site inspections.

Lithium battery powered, 8-hour operating time.

Rugged and durable with triple protection against water, oil, and dust. Extended service life and excellent interference resistance, lasting several times longer than conventional flaw detectors.

Large high-brightness display suitable for inspections in direct sunlight or enclosed spaces like tunnels.

Alarm: Audible alarm with LED indicator.

Product parameters

| Scan Range (mm) | 0~10000 |

| Vertical Linear Error | ≦2% |

| Horizontal Linearity Error | ≤0.1% |

| Flaw Detection Sensitivity Margin | ≥60dB (200mm deep φ2 flat-bottomed hole) |

| Dynamic Range | ≧32dB |

| Resolution | ≧40dB |

| Frequency Range (MHz) | 0.5 to 20 |

| Gain Adjustment (dB) | 0 to 120 |

| Material Sound Velocity (m/s) | 1000 to 9999 |

| Echo Suppression | 0 to 80% |

| Operating Temperature (°C) | -27 to 70 |

| Dimensions (mm) | 240 × 160 × 40 |

| Flaw detection recording | Yes |

| Pulse/emission intensity | Adjustable |

| Weight (kg) | 1.3 |

| Optional Accessories | Probes, Standard Test Blocks, Laptop Computer, PC Communication Software, BNC Cable |

+86 19353291814

+86 19353291814