Bottle Body Leakage and Seal Strength Tester

- Product Number:LD-MF03C

- Product Difference:Inspection Items: Bottle Cap + Bottle Body

Product Introduction

Bottle Body Leakage and Seal Strength Tester (also known as Positive Pressure Seal Tester) is professionally designed for quantifying the seal strength, heat-sealing quality, burst pressure, and leak performance of various sealed edges in flexible packaging and sterile packaging formed by heat-sealing or adhesive bonding processes. It analyzes indicators such as compressive strength and burst strength of materials used in flexible packaging bags. Quantitative assessment of seal integrity, cap-to-bottle detachment strength, and material stress intensity for tamper-evident plastic bottle caps; evaluation of bottle body sealing, compression resistance, and burst strength. Utilizing positive pressure testing simulates real-world conditions to evaluate seal strength, leakage performance, and pressure limits, providing reliable quality control data for packaging across industries.

Partial Standards Applied: ASTM F1140, ASTM F2054, YBB 00252005, YBB 00162002, ISO 11607-1, ISO 11607-2, GB/T 10440, GB 18454, GB/T 17876, BB/T 0025.

Applicable to the following fields:

① Plastic composite bags: Suitable for burst strength testing of various packaging bags including plastic films, aluminum foils, paper-plastic composites, and aluminum-plastic composites.

② Creep Testing: Suitable for evaluating the creep performance of various packaging bags, boxes, etc.

③ Creep-to-Rupture Testing: Suitable for assessing the creep-to-rupture performance of various packaging bags, boxes, etc.

④ Blister Packaging Burst Testing: Suitable for pressure resistance testing of various blister packaging.

⑤ Tamper-Evident Caps: Suitable for sealing performance testing of various tamper-evident caps. These include caps for mineral water/purified water bottles, beverage bottles, vegetable oil drums, condiment bottles (soy sauce, vinegar, cooking wine, etc.), easy-open three-piece cans (beverage cans, etc.), and paper-based packaging cans (cylindrical, various potato chips/shrimp crackers).

Product Features

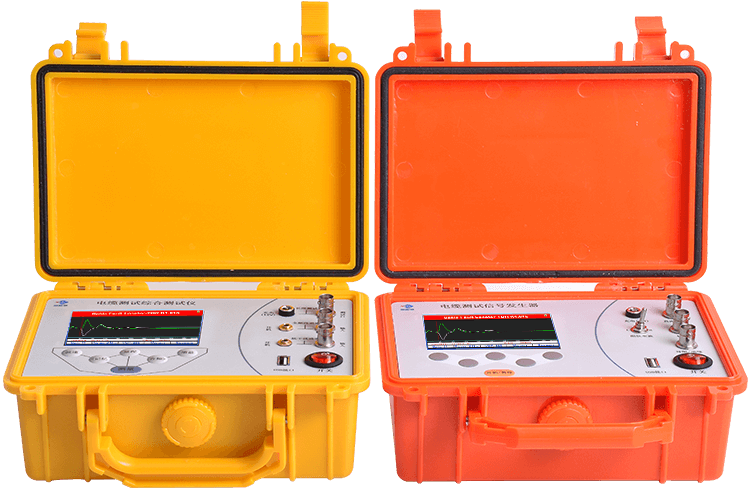

7-inch touchscreen control with one-touch operation and intuitive interface, supporting remote upgrades and maintenance.

Features imported components from renowned SMC brand, employing positive pressure design principles for simple operation and stable, reliable performance.

Built-in pressure sensor for precise measurement of internal sample pressure.

Real-time display of pressure trends during testing with intelligent data statistics.

Supports burst testing, creep testing, and creep-to-burst testing modes.

Mini printer and USB universal data interface for convenient data output and transfer.

Built-in data storage capacity for up to 2000 entries, meeting large-volume storage requirements.

Multi-level user permission management with password login.

Complies with China GMP requirements for data traceability, meeting pharmaceutical industry needs.

Chinese-English bilingual interface switching to accommodate different language requirements.

Product parameters

| Model | MF03A | MF03B | MF03C |

| Sample Type | Packaging Bag | Cap | Cap + Body |

| Test Range | 0~1MPa/0~145.2 psi (Standard) | ||

| Resolution | 0.1 kPa/0.01 psi | ||

| Pressure Accuracy | ±1%FS | ||

| Inflation Nozzle | Φ10 mm (Customizable) | ||

| Inflation Flow Rate | 0.1~10 L/min | ||

| Pressure Holding Time | 0 sec~9999 sec | ||

| Air Source | Air (User-supplied) | ||

| Air Source Pressure | 0.6MPa~0.7MPa (87psi~101psi) | ||

| Air Supply Interface | Φ6 mm polyurethane tubing | ||

| Main Unit Dimensions | 204mm(L)×211mm(W)×112mm(H) | ||

| Fixture Dimensions | Test Fixture 210(L)*300(W)*311(H)mm | Sealing Barrel (ID) Φ230mm × 280mm(H) | Sealing Barrel (ID) Φ230mm × 280mm(H) |

| Power Supply | AC220V /50Hz | ||

| Net Weight | Main Unit 1.8KG | ||

| ◇ For users with special requirements, our company can provide customized production within our capabilities to meet user needs. | |||

+86 19353291814

+86 19353291814