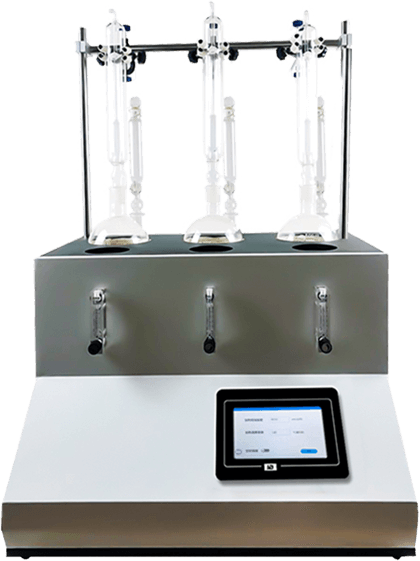

Traditional Chinese Medicine Sulfur Dioxide Distillation Apparatus

- Product Number:LD-ZL3S

- Product Difference:Three sets of distillation tests to determine sulfur dioxide residue levels in medicinal materials and sliced herbs

Product Introduction

The Traditional Chinese Medicine Sulfur Dioxide Distillation Apparatus processes herbal materials via distillation according to pharmacopoeia-specified testing methods. Sulfite compounds in the sample are converted to sulfur dioxide through acid treatment, then carried by a nitrogen stream into an absorption flask containing hydrogen peroxide. where hydrogen peroxide oxidizes them into sulfate ions. The residual sulfur dioxide content in the herbs and sliced materials is then determined via acid-base titration and calculated.

Strictly adhering to pharmacopoeia requirements, this product integrates heating, distillation, water circulation, and nitrogen blowing functions into one unit. It can process 3-5 samples (blank samples, parallel samples) simultaneously, thereby enhancing the precision of test data and reducing working time.

The Traditional Chinese Medicine Sulfur Dioxide Distillation Apparatus series complies with Method 1 of General Rule 2331 in Volume IV of the Pharmacopoeia of the People's Republic of China. It is used to determine residual sulfur dioxide in herbal materials or slices treated with sulfur fumigation.

This instrument is primarily suitable for various traditional Chinese medicine manufacturers, research institutes, and food production enterprises related to sulfur fumigation, serving routine sulfur dioxide residue determination.

The Traditional Chinese Medicine Sulfur Dioxide Distillation Apparatus mainly consists of a heating module, distillation module, cooling water circulation module, and nitrogen blowing module. The heating module features three-speed heating rate control (high, medium, low) via a precise control panel. The distillation module utilizes high borosilicate material, offering excellent heat resistance and durability. The cooling water circulation system can be equipped with an external cooling water circulation unit (internal option available) to ensure effective cooling. The nitrogen blowing module supports connection to an external nitrogen generator or nitrogen cylinder and is fitted with a high-precision gas flow meter to strictly control the nitrogen blowing rate.

Product Features

Sealed infrared ceramic heating jacket ensures excellent heat retention and high heating efficiency while preventing equipment damage from liquid spills.

Full touchscreen control with intuitive human-machine interface for simple, easy operation.

Heating units feature independent temperature control with adjustable power settings.

Heating countdown function with audible alerts and automatic shutdown.

Magnetic stirring device ensures uniform sample mixing during experiments.

Equipped with an independent precision nitrogen flow control system. Compatible with nitrogen generators.

Product parameters

| Display Method | LCD Touchscreen |

| Heating Method | Far-infrared Ceramic Heating (No Open Flame, Low Power Consumption, High Efficiency) |

| Nitrogen Blow Control | Main unit features a master nitrogen interface, Individual nitrogen flow rates for each port can be controlled separately via flow meters |

| Cooling Method | External cooling water circulation unit (internal option available), no external tap water cooling required |

| Temperature Control | Built-in micro-boiling heating control system, temperature range 0-200°C |

| Number of Distillation Units | 3 sets |

| Distillation Flask Specifications | Standard: 1000ml flask |

| Receiving flask specifications | Standard: 100ml×3 conical flasks |

| Rated power | 2450W |

| Rated voltage | 220V/50Hz |

| Overall dimensions (mm) | 930*520*850 |

| Earth leakage protection | Yes |

| Dry-burn protection | Yes |

| Application Range | Temperature Range -10~100℃ |

| Temperature Fluctuation ±0.05℃ | |

| Digital Display Resolution 0.01℃ | |

| Working Chamber Volume 250×200×150mm³ | |

| Working Chamber Opening 180×140mm² | |

| Chamber Depth 150mm | |

| Circulation Pump Flow Rate 6L/min | |

| Overall Dimensions (W×D×H) 320×370×655mm |

+86 19353291814

+86 19353291814