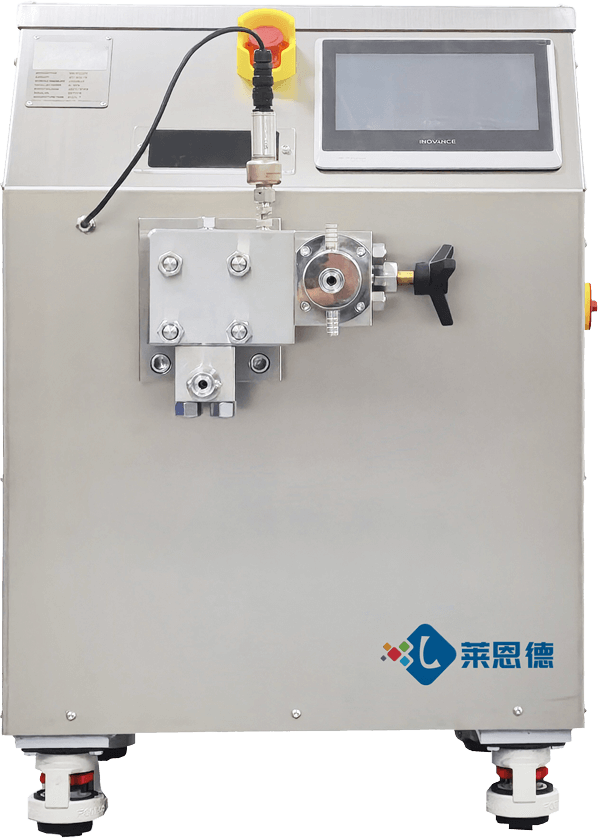

High-Pressure Homogenizer for Food and Beverage

- Product Number:LD-JZ6000

- Product Difference:Design pressure: 2000 bar Operating pressure: 1000 bar (Maximum flow rate: 50–60 liters per hour; Minimum processing volume: 60 milliliters)

Product Introduction

High-Pressure Homogenizer for Food and Beverage Dispersion Principle: The function of dispersion lies in uniformly distributing different components within the same system, breaking up or refining insoluble particles in liquids to form stable, homogeneous solutions.

Under the force of the plunger, the material enters the dispersing valve where it is pressurized and discharged. During this process, the material undergoes multiple actions: cavitation, shear effects, impact effects, high-frequency vibration from intense turbulence, shear forces at the edges of the dispersing valve, and impact forces against the dispersing valve's retaining ring. This achieves the effect of material pulverization.

Product Features

High-pressure homogenization ensures uniform particle size distribution, delivering excellent material processing results with consistent quality. Suitable for processing materials of varying viscosities across multiple industries.

Stainless steel chamber + leak-proof sealing design offers corrosion resistance and easy cleaning, meeting hygiene standards with residue-free operation and low wear.

Adjustable pressure + multiple safety protections ensure simple operation, stable performance, low noise, easy maintenance, and suitability for continuous production.

Product parameters

| Processed Products | Suspensions, emulsions, etc. |

| Maximum Feed Particle Size | < 500 microns |

| Maximum Feed Temperature | < 90 °C |

| Throughput | Flow rate adjustable, maximum flow rate up to 50-60 liters/hour |

| Minimum batch size | 60 milliliters |

| Number of dispersion stages | Single stage |

| Operating pressure | Design pressure 2000 bar, working pressure 1000 bar |

| Pressure gauge | Hygienic Pressure Sensor |

| Main Motor | Swiss ABB / Siemens 5.5Kw |

| Voltage and Frequency | 380V, 50Hz, 3-phase |

| Grade | Sanitary Grade |

| Plunger | 1 piece |

| Internal Cooling | Fan |

| Inlet/Outlet Connection | Tri-Clamp Quick Connect |

| Maximum Cleaning Temperature | < 90 °C |

| Water Consumption During Cleaning/Sterilization | 30 liters/hour |

+86 19353291814

+86 19353291814