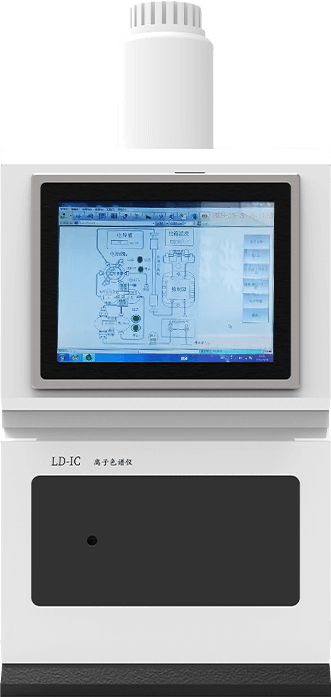

Ion Chromatograph

- Product Number:LD-IC-

- Product Difference:Anion System, All-in-One Design (no computer required), Real-time Display of Instrument Operating Parameters and Status

Product Introduction

The all-new generation ion chromatograph features a 12.1-inch flat-panel industrial computer all-in-one design (no external computer required), displaying real-time instrument parameters and status. One-touch operation enables electric valve injection, instrument power cycling, maintenance, and access to user manuals for unparalleled convenience. Core components are independently developed with proprietary intellectual property rights. The integrated design combines the ion chromatograph main unit, eluent generator, industrial control computer, and chromatography workstation into a compact structure with minimal flow paths, significantly reducing peak broadening caused by flow dynamics.

Integrated Temperature-Controlled Chamber: Chromatography columns, suppressors, conductivity cells, and amplification circuits are all maintained within the same temperature-controlled system, minimizing temperature drift and baseline noise in the conductivity detector. Multiple built-in leak detectors and low-water alarms provide comprehensive safety monitoring. PLC-controlled components are unified under a centralized software control system displayed on the computer screen, enabling intuitive mouse-based operation where what you see is what you control.

Product Features

Features a 12.1-inch flat-panel industrial control computer all-in-one design (no separate computer required), displaying real-time instrument operating parameters and status.

One-button operation for electric valve injection, instrument power cycling, maintenance, and accessing user manuals—convenient and efficient.

Integrated design combines the ion chromatograph main unit, eluent generator, industrial control computer, and chromatography workstation into a compact structure with minimal flow paths.

Continuously auto-regenerating electrochemical micro-membrane suppressor with online auto-regeneration, high suppression capacity, low background conductivity, low noise, stable baseline, and maintenance-free operation.

Dedicated ion chromatography workstation with full Chinese display, transmitting digital signals to a computer via USB for chromatographic data acquisition and processing.

Built-in multiple leak detectors and low-water alarms for comprehensive safety monitoring.

Product parameters

| High-Pressure Infusion Pump | |

| Microprocessor-controlled dual-plunger reciprocating pump employs advanced intelligent control algorithms to minimize flow pulsation | |

| Material | Damping-free PEEK pump head with PEEK tubing, suitable for eluents with pH 0–14 and reverse-phase organic solvents |

| Flow Range | 0.001~9.999 ml/min, increment 0.001 ml/min |

| Flow Setpoint Error | ≤0.1% |

| Flow Stability | ≤0.1% |

| Working Pressure | 35MPa |

| Overpressure Protection | When working pressure exceeds or falls below the set upper or lower limits, the pump will automatically shut down and trigger an alarm |

| Conductivity Detector | |

| Principle | Pentapolar Conductivity Detector |

| Electrode Material | Passivated 316L Stainless Steel |

| Baseline Noise | ≤0.002 μS/cm |

| Baseline drift | ≤0.008 μS/cm·30 min |

| Minimum Detection Concentration | ≤0.0005 μg/mL (as Cl-) |

| Instrument Linearity | ≥0.9995 |

| Quantitative Repeatability | ≤0.1% (calculated as Cl-) |

| Qualitative Repeatability | ≤0.1% (based on Cl-) |

| Measurement Range | 0~50000 μS/cm |

| Resolution | ≤0.0020 nS/cm |

| Detection Cell Volume | 0.8 μL |

| Operating Pressure | ≤10 MPa |

| Conductivity Measurement Range | 0-50000 μS, 10-range adjustable |

| Anion and Cation Inhibitors | |

| Advantages | Continuous Automatic Regeneration Electrochemical Micro-Membrane Suppressor Online automatic regeneration High suppression capacity Low background conductivity Low noise Stable baseline Maintenance-free |

| Anti-pollution, excellent pressure resistance, long service life, wide operating range (pH 0-14) | |

| Compact size, rapid stabilization time (≤12 minutes), and excellent reproducibility | |

| Flow Path System | |

| Manufacturing Material | The flow path system is manufactured using PEEK material, offering excellent versatility and compatibility with strong acid and strong alkali eluents |

| Organic Solvent Compatibility | 100% organic solvent compatibility facilitates user analysis, rinsing, and maintenance of complex samples |

| Optimized Design | Compact structure with minimal flow path length significantly reduces peak broadening caused by fluid dynamics |

| Safety Monitoring | Multiple built-in leak detectors and low-water alarms provide comprehensive safety monitoring |

| Built-in Chromatography Workstation | |

| Digital-to-Analog Conversion | 24-bit high-precision, high-sensitivity digital-to-analog conversion |

| Display & Transmission | Dedicated ion chromatography workstation with full Chinese display. Digital signal transmission via USB to computer for chromatographic data acquisition and processing |

| Automated Operation | Automatically receives analysis data and controls instrument settings. Features automatic negative peak detection and baseline subtraction. Performs automatic parameter integration and generates reports |

| Integrated temperature control system for chromatographic column, suppressor, conductivity cell, and amplification circuit | |

| Operating Method | The conductivity cell, flow path system, separation column, suppressor, and amplification circuit are thermostated on a single temperature-controlled base within the column oven, with a temperature control accuracy of 5–65°C ±0.01°C. Furthermore, the instrument column oven employs an insulated structure to maintain constant temperatures for the detection system, flow path, columns, suppressor, conductivity cell, and amplification circuit. This ensures high-quality separation and detection accuracy while mitigating temperature drift and baseline noise in the conductivity detector |

| Built-in Rinse Solution Generator | |

| Advantages | Uses only high-purity water, eliminating the need for manual preparation of any chemical reagents. Generates isocratic or gradient high-purity eluents online, reducing baseline drift, enhancing stability, and simplifying workflows |

| Online Automatic Degassing System | |

| Degassing Efficiency | At 25°C, when the oxygen content of the inlet mobile phase is 8 PPM, the oxygen content of the outlet mobile phase is 2 PPM (Flow rate: 1.5 mL/min) |

| Vacuum Pressure | -0.018 MPa |

| Flow Rate | 5 mL/min |

| Separation Capability (The types of ions that can be separated by configuring different anion and cation separation columns) | |

| Configure domestic anion separation column | Single-injection analysis: Fluoride, Chloride, Nitrite, Phosphate, Bromide, Nitrate, Sulfate |

| Configure imported anion separation column | Single-injection analysis: Fluoride, bromate, chloride, nitrite, phosphate, bromide, nitrate, sulfate, chlorite, perchlorate, dichloroacetic acid, trichloroacetic acid, etc. |

| Configure imported cation separation column | Single-injection analysis: Li+, Na+, NH4+, K+, Ca2+, Mg2+, Sr2+, Ba2+, etc. |

| Basic Parameters | |

| Dimensions and Weight | Weight: Approximately 30kg; Dimensions (mm): Length 500, Width 400, Height 600 |

+86 19353291814

+86 19353291814