Rice Appearance Quality Tester

- Product Number:LD-DM

- Product Difference:Precise automatic detection of various appearance quality indicators for different types of rice (polished rice, brown rice, glutinous rice, etc.)

Product Introduction

Rice Appearance Quality Analyzer automatically measures the area, length, width, aspect ratio, diameter, and roundness of each grain. It enables precise automated detection of various appearance quality indicators for all rice types (polished rice, brown rice, glutinous rice, etc.), supporting multi-parameter, batch-based automated analysis.

Compliant with national standards GB/T1350 Rice Grains, GB/T17891 Premium Rice Grains, or GB1354-2018 Rice; Ministry of Agriculture standards [Rice] NY/T2334-2013, Rice Grain Shape Classification LS/T6116-2016, Grain Industry Standard Rice LS/T 3247—2017, GB/T 35881-2018 Grain and Oil Inspection - Image Analysis Method for Determining Yellow Grain Content in Rice.

Capable of automatically measuring and analyzing 1 grain or more of rice samples in a single run: chalkiness/chalkiness rate, broken rice rate and small broken rice rate, number of whole polished grains, whole polished rice rate, national standard grade of rice transparency, yellow grains, foreign grains, imperfect grains (immature grains), and crack rate. It also measures glutinous rice's shadowy grain rate, disease spot or yellowing rate, and brown rice germ rate.

It can automatically measure and analyze one or more black rice samples at once for: blackness, black rice rate, whole black rice rate, broken rice rate, and small broken rice rate, fully complying with the relevant testing indicators in the NY/T 832-2004 standard.

Product Features

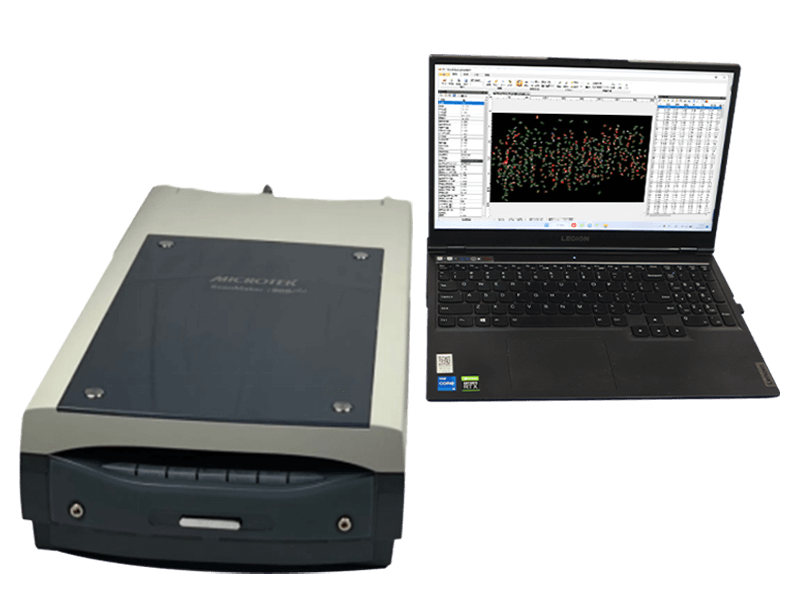

Equipped with a dual-light-source color scanner featuring 4800×9600 optical resolution and extended A4 scanning area for imaging. Transparent scanning area: 30cm×20cm. Minimum pixel size: 0.0053mm ×0.0026mm.

Features sample barcode and electronic balance RS232 data software interfaces. Compatible seed size range: 0.25-20mm. Automatic counting accuracy ≥99%, achieving 100% accuracy after interactive correction.

Equipped with automatic learning and recognition capabilities, enabling automatic separation of agglomerated rice grains and seeds, and performing automated classification analysis.

Automatically measures individual particle area, length, width, aspect ratio, diameter, and roundness.

Cloud platform support enables analysis data storage for remote access anytime, anywhere.

Built-in bilingual (Chinese/English) display with one-click switching for seamless operation.

Capable of large-batch automatic analysis processing and result output.

Equipped with screen recording functionality to capture and save experimental procedures.

All analysis images, distribution charts, and result data can be saved. Analysis results export to Excel spreadsheets, including analysis markup diagrams, as well as sorting charts and measurement charts sorted by width, length, area, etc.

Product parameters

| Optical Resolution | 4800×9600 |

| Scanner | A4-extended dual-light source color scanner |

| Measurement Data | Automatically measures area, length, width, aspect ratio, diameter, and roundness |

| Measurement Error | Length ≤ ±0.05mm, aspect ratio ≤ ±0.05, repeatability ≤ ±0.02; Whole grain rate and broken grain rate ≤±1.0%, repeatability ≤±0.25% |

| Environmental Conditions | Temperature 10~30℃, relative humidity ≤85%, avoid strong light exposure, place instrument on a stable workbench, free from strong mechanical vibration and electromagnetic interference |

| Evaluation Method | Dedicated processing software for general-purpose computers |

| Power Requirements | 220V±10%, 50Hz |

+86 19353291814

+86 19353291814