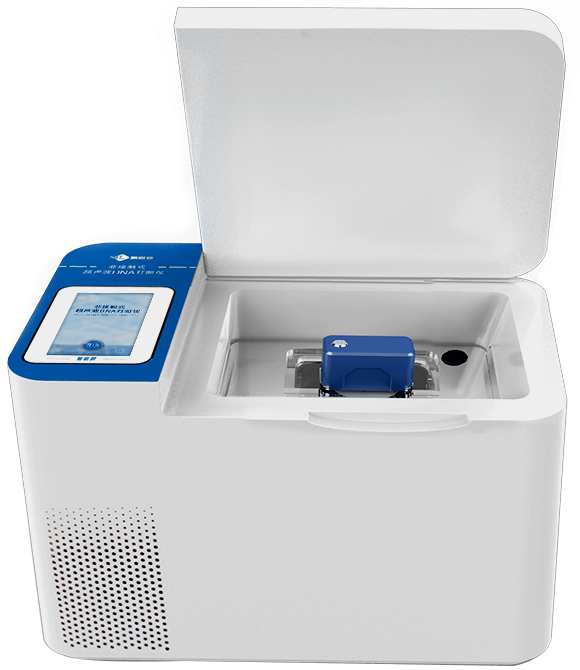

DNA Fragmenter

- Product Number:LD-D300

- Product Difference:20-400 kHz mixed-frequency ultrasonic function precisely breaks DNA molecular chains

Product Introduction

The principle of DNA fragmenters is based on mechanical vibrations and cavitation effects generated by ultrasonic waves. High-frequency electrical signals produced by the ultrasonic generator are converted into mechanical vibrations via a transducer, which are then applied to the liquid containing the DNA sample.

Under ultrasonic influence, microscopic bubbles form within the liquid medium. These bubbles rapidly expand and implode, generating intense shock waves and microjets capable of penetrating cell membranes and nucleic acid molecules to precisely cleave DNA molecular chains.

DNA shearing instruments find applications in bacterial cell disruption, protein extraction, DNA fragmentation for next-generation sequencing (NGS) samples, immunoprecipitation experiments, fungal spore disruption, emulsification, homogenization, accelerated dissolution, and catalytic reactions. They play a particularly crucial role in processing DNA samples for molecular biology research.

① Genomics: NGS library preparation (WGS, WES), metagenomics research

② Next-Generation Sequencing (NGS): DNA fragmentation in library preparation

③ Epigenetics Research: Sample processing for ChIP-seq, ATAC-seq, and similar experiments

④ Molecular Diagnostics: Fragmentation of extracted DNA from FFPE samples

⑤ Synthetic Biology: DNA fragment preparation prior to genome assembly

⑥ Forensic Analysis: Standardized processing of trace DNA samples

Product Features

High throughput and flexible configuration accommodate test samples of varying capacities, meeting diverse experimental requirements.

The battery-powered rotary motor simplifies installation, enabling rapid deployment of the equipment.

External low-temperature water bath interface allows connection to a chiller for precise sample temperature control, preventing sample denaturation—ideal for temperature-sensitive sample processing.

Automatic fault alarm (or protection) function continuously monitors device status, promptly detecting and alerting to abnormalities to ensure safe and stable operation.

7-inch medical-grade LCD touchscreen with high resolution, intuitive interface, and smooth operation.

Flexible ultrasonic parameter settings: Ultrasonic duration, interval time, power level, and alarm temperature are freely configurable. Sample temperature monitoring and display ensure excellent experimental reproducibility and high result reliability.

Each sample is processed in a separate, fully enclosed test tube, effectively preventing cross-contamination and ensuring accurate experimental results.

20-400 kHz hybrid ultrasonic function with adaptive frequency capability accommodates diverse sample processing requirements and enhances disruption efficiency.

Product parameters

| Ultrasonic Frequency | 20-400KHz mixed-frequency ultrasonic capability, three selectable settings, with adaptive frequency adjustment ① Low-frequency 20-30, ② Mid-frequency 20-100, ③ High-frequency 20-400 |

| Ultrasonic Nominal Power | 100~1000W, freely adjustable power |

| Ultrasonic Time Setting | Total time 0.1-999min, Single Ultrasonic Duration 0.1-99.9s |

| Display | 7-inch TFT Resistive Touchscreen |

| Ultrasonic Tank Volume | 17*16*10 (cm) |

| Adjustment Method | Power Setting |

| Temperature Sensor | Yes |

| Temperature Control Range | 2~40℃ (Optional Constant Temperature Device) |

| Alarm Function | End Reminder, Overload Protection, over-temperature alarm |

| Control Method | TFT Touchscreen |

| User Protection | User Password Protection |

| Operational Voice Alarm | Buzzer Alarm |

| Chinese/English Switching | Optional English Version |

| Transducer | High-strength titanium alloy + aluminum-magnesium alloy |

| Power Input Voltage & Power | 220V±5%/50Hz 1200W |

| Dimensions & Weight | 580mm*283mm*370mm, approximately 14kg |

+86 19353291814

+86 19353291814