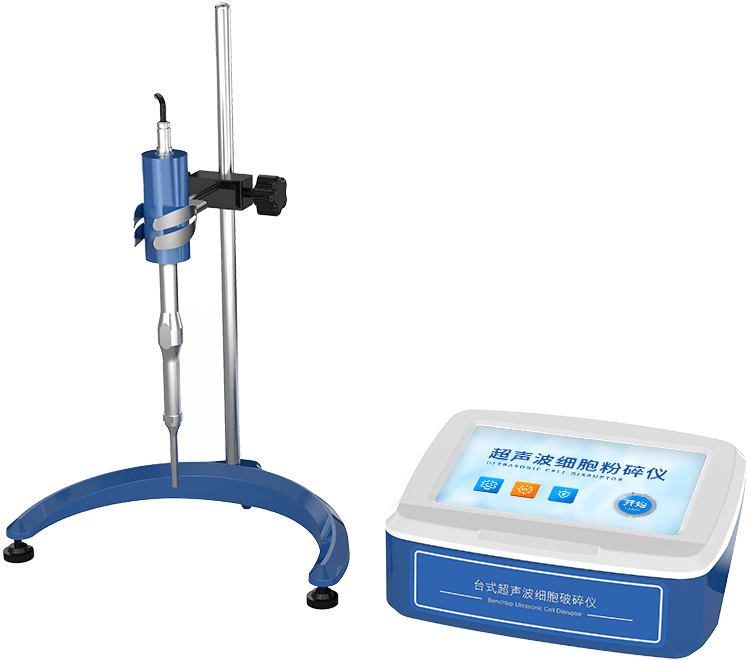

Stand-Mounted Ultrasonic Cell Disruptor

- Product Number:LD-TC650

- Product Difference:Stirrer model, capable of performing extraction, grinding, emulsification, homogenization, suspension preparation, mutation, aerosol generation, and accelerated desolvation

Product Introduction

The stand-mounted ultrasonic cell disruptor is a versatile, multi-purpose instrument that utilizes intense ultrasonic waves to generate cavitation effects in liquids for sonication processing. It can be used for disrupting animal and plant tissues, cells, bacteria, and spore cultures, while also serving for emulsification, separation, dispersion, homogenization, extraction, degassing, cleaning, and accelerating chemical reactions.

Our company independently develops and manufactures this stand-mounted ultrasonic cell disruptor. It features comprehensive functionality, a modern design, and reliable performance. The instrument incorporates a large LCD display with centralized microcomputer control, offering functions such as ultrasonic output, interval time, ultrasonic power, sample temperature monitoring and display, automatic frequency tracking, and automatic fault alarms. It is suitable for teaching, research, and production in fields including biochemistry, microbiology, medicinal chemistry, surface chemistry, physics, zoology, agronomy, medicine, and pharmaceuticals.

The stand-mounted ultrasonic cell disruptor utilizes the dispersive effect of ultrasonic waves in liquids to induce cavitation, thereby breaking down solid particles or cellular tissues within the liquid. The ultrasonic cell disruptor consists of two main components: an ultrasonic generator and a transducer.

The ultrasonic generator converts mains electricity into 20-25KHz alternating electrical energy supplied to the transducer. The heart of the transducer is a barium zirconate titanate piezoelectric crystal. This crystal undergoes elastic expansion and contraction at a frequency of 20-25KHz in response to the alternating voltage, causing the transducer to vibrate longitudinally. These vibrations are transmitted through a titanium alloy horn immersed in the biological solution, generating cavitation effects that excite violent vibrations in the biological particles within the medium.

The stand-mounted ultrasonic cell disruptor can be used to pulverize animal and plant cells, bacteria, spores, or tissues, and to disperse rare earths and various inorganic mineral powders. It is an ideal device for accelerating chemical, biological, and physical reaction rates and for accelerating liquid degassing. It can prepare emulsions with particle sizes approaching one-hundredth of a micron, homogenize “difficult-to-mix” mixtures, polymerize certain substances, and precipitate others.

In summary, ultrasonic pulverizers perform multiple functions including extraction, pulverization, emulsification, homogenization, suspension preparation, mutation induction, aerosol generation, accelerated desolvation, crystallization, and preparation of various biological samples for electron microscopy.

Product Features

Split-design: Separation of the main unit and transducer reduces vibration impact on the instrument, extending its service life.

Adjustable stand: Height and angle adjustable to accommodate various containers (test tubes, beakers, reaction vessels, etc.).

Features intelligent MCU digital integrated circuitry supporting intermittent/continuous operation modes.

Includes test and run modes with pause or stop functionality.

10.1-inch medical-grade LCD touchscreen with high resolution, intuitive interface, and smooth operation.

Equipped with an electrically operated platform lift, LED illumination system, and UV sterilization function.

Ultrasonic on time, ultrasonic off time, and total time can be set with precision down to 0.1 seconds.

Stores up to 256 sets of engineering parameters for convenient configuration and retrieval by operators.

Features automatic horn matching, automatic frequency tracking, and automatic fault alarm (or protection) functions.

Ultrasonic probe constructed from TC4 military-grade titanium alloy, offering high strength, excellent corrosion resistance, and superior heat tolerance.

Low-noise metal housing with high-quality sound-insulating material in the sandwich layer ensures excellent noise reduction and a clean, hygienic working chamber.

Rear expansion port supports manual switches or foot switches for precise manual control, or external device integration (e.g., temperature controllers, stirrers).

Product parameters

| Display | 10.1-inch TFT resistive touchscreen |

| Crush Capacity | 0.1–500 ml (requires optional horn) |

| Single Ultrasonic Duration | 0.1–99.9S |

| Single Interval Duration | 0–99.9S (0 indicates continuous mode) |

| Total Time | 0.1–999.9 minutes |

| Adjustment Method | Power or PWM (optional) |

| Alarm Function | End notification, overload protection |

| Parameter Storage | Up to 256 sets, automatic parameter storage |

| Control Method | TFT touchscreen Manual control (optional) |

| Optional Features | Thermostat Foot switch |

| Interfaces | Power interface Transducer interface Foot switch interface |

| User Protection | User password protection |

| Operational Voice Alarm | Buzzer Alarm |

| Chinese/English Switching | Optional English Version |

| Transducer | Aviation-Grade Magnesium-Aluminum Alloy Transducer |

| Horn | TC4 Military-Grade Titanium Alloy |

| Power Supply | 220V±5%/50Hz |

| Power | 20-650W |

| Transducer Frequency Range | 20-25KHz |

| Optional High Borosilicate Thermostatic Cup ml | 50, 100, 250, 500, 1000 |

| Optional Horns | Φ2, Φ3, Φ6, Φ8, Φ10, Φ12, Φ15 |

| Dimensions & Weight | 300mm*240mm*130mm, approximately 1.9kg |

+86 19353291814

+86 19353291814