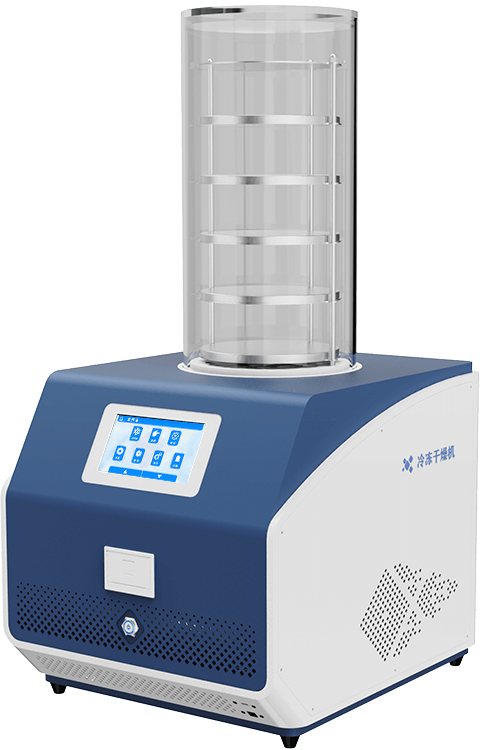

Sealing Cap Heating Freeze Dryer

- Product Number:LD-DG20+

- Product Difference:Freeze-drying area: 0.09m² × 3, a device that utilizes vacuum freeze-drying technology for material drying

Product Introduction

The capping heating freeze dryer is a device that utilizes vacuum freeze-drying technology to dry substances. Its fundamental principle involves first freezing the water-containing material into a solid state, then employing the sublimation principle to cause the water to directly transition from a solid to a gaseous state, thereby removing moisture and preserving the material.

Vacuum freeze-drying is a technology that employs sublimation for drying. The material is rapidly frozen at low temperatures, then placed in a suitable vacuum environment where frozen water molecules directly sublimate into vapor and escape. This process avoids concentration due to dehydration. The dried material exhibits a dry, sponge-like porous structure with minimal volume change. It readily rehydrates upon re-freezing, significantly preventing physical, chemical, and biological alterations in the dried substance.

Cap-sealing freeze dryers are widely used in pharmaceuticals, biological products, food, and other industries, offering advantages such as excellent drying efficiency, extended shelf life, and superior rehydration properties.

① Pharmaceutical Industry: Freeze dryers are extensively applied in pharmaceuticals, primarily for producing and preserving drugs, biological products, and medical devices. This technology removes moisture to extend shelf life, maintain drug efficacy and biological product activity, while facilitating transportation and storage.

② Food Industry: In food processing, freeze dryers preserve fruits, vegetables, meats, seafood, and seasonings. This technology retains original color, aroma, and nutrients while extending shelf life and enabling convenient storage and transport.

③ Chemical Industry: Freeze dryers produce and preserve catalysts, chemical raw materials, pigments, and other products. By removing moisture and volatile components, it ensures product quality and purity.

④ Agricultural Sector: In agriculture, freeze-drying technology is used for preserving and germinating plant seeds. Removing moisture extends storage time while maintaining seed germination rates.

⑤ Other Fields: Freeze-drying technology also finds applications in environmental protection, energy, and scientific research. Examples include treating sludge and wastewater, producing fuels, and conducting material research and preparation.

Product Features

Condensation System

(1) Original imported hermetic compressor delivers rapid cooling and higher efficiency; new eco-friendly refrigerant is environmentally conscious and fully compliant with national environmental standards.

(2) Cold trap maximum water capture capacity ≥3KG, operating temperature ≤-60°C, uniform inner wall temperature, and professional gas flow design enable both effective freeze-drying and water capture, protecting the vacuum pump.

(3) Cold trap features external coils with smooth, unobstructed interior, incorporating sample pre-freezing functionality—eliminating the need for additional ultra-low temperature freezers or liquid nitrogen freezing equipment.

(4) Constructed from corrosion-resistant 304 stainless steel, its polished surface facilitates efficient defrosting.Vacuum System

(1) High-seal vacuum chamber achieves ultimate vacuum ≤10 Pa.

(2) Equipped with a vacuum micro-adjustment ball valve for manual precision vacuum control.

(3) Custom-designed vacuum generator specifically for freeze dryers, with a pumping speed of 2 L/s to rapidly achieve chamber vacuum.

(4) Pirani vacuum gauge for precise chamber pressure measurement, ensuring accurate and reliable vacuum values.

(5) Equipped with KF25 quick-connect clamps for secure vacuum pump-to-chamber sealing.

(6) Optional vacuum pump oil mist filter maintains laboratory environment by reducing oil contamination.Drying Chamber System

(1) Freeze-drying area up to 0.19m² (standard model), with φ200mm sample trays. Supports expansion with multi-manifold freeze-drying bottles and flask-shaped bottles for increased capacity. (Equipped with multi-manifold bell jar)

(2) The bell jar is constructed from highly transparent material, offering corrosion resistance and shatterproof properties for easy observation of the freeze-drying process.

(3) The drying rack supports capping functionality, enabling freeze-drying of samples in containers requiring capping, such as vials (capping type).

(4) The number of shelf layers is adjustable, allowing appropriate increases or decreases based on sample quantity.

(5) Shelves feature heating capability to further release bound water from samples (heated type).

(6) Equipped with Class A temperature sensors to accurately monitor temperatures throughout the reaction drying chamber.Control System

(1) Features a 7-inch true-color LCD touchscreen with clear display. User-friendly interface ensures intuitive operation.

(2) Clearly displays all parameters including temperature, vacuum level, and runtime, enabling full control over the freeze-drying process.

(3) Automatically saves data for real-time viewing and historical analysis. Data transfer via USB allows for further analysis.

(4) Built-in compressor and vacuum pump maintenance reminders automatically alert users when lubrication or replacement is required.

(5) Password protection facilitates access control, preventing unauthorized operation by non-professionals.

(6) Multiple sample protection mechanisms, such as disabling vacuum pump activation when cold trap temperature is too high, prevent sample boiling and damage.

Product parameters

| Model | Standard Type | Pressure-Sealed Type | Heated Type | Remarks |

| Freeze-Drying Area | 0.19 m² | 0.12 m² | 0.09 m² | Can be paired with either standard or multi-manifold bell jars |

| Water capture capacity | 3 kg/batch | |||

| Number of freeze-drying bottles | 8 pcs | Compatible with manifold bell jar | ||

| Material tray dimensions | Φ200 mm | |||

| Material tray spacing | 70 mm | 65 mm | 85 mm | |

| Number of Material Trays | 6 pcs | 4 pcs | 3 pcs | |

| Cold Trap Dimensions | Φ250 mm * 150 mm | |||

| Cold Trap Minimum Temperature | ≤ -55 ℃ | |||

| Ultimate Vacuum | < 10 Pa | No Load | ||

| Baffle Heating | / | 70 ℃ | Heated Type | |

| Temperature Uniformity | / | ±1 ℃ | Heated Type | |

| Noise | < 78dB | |||

| Rated Voltage | AC 220V 50Hz | |||

| Power | 0.95 Kw | |||

| Dimensions | L: 500 mm * W: 550 mm * H: 450 mm | Plus bell cover height 500mm | ||

+86 19353291814

+86 19353291814