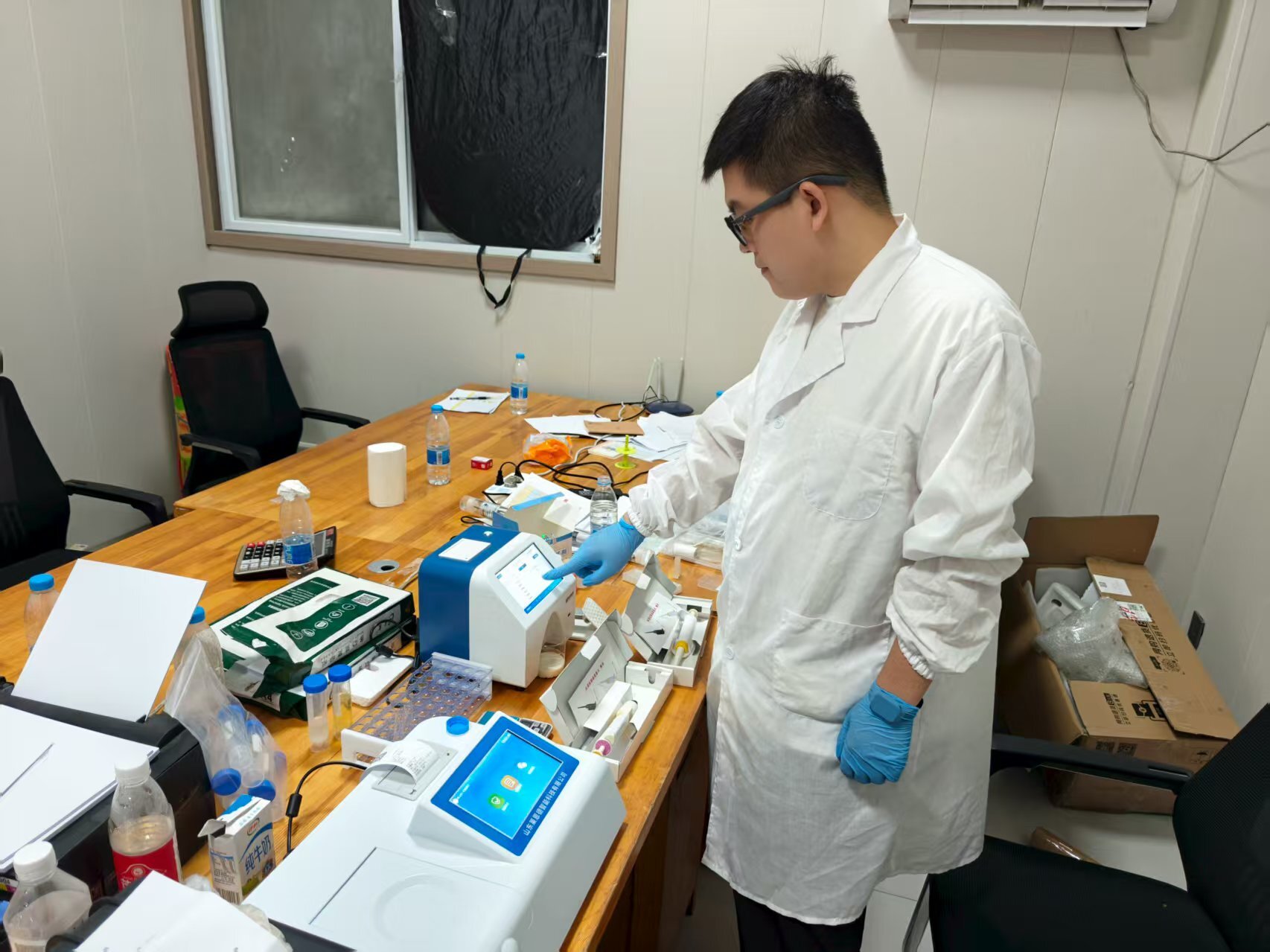

The Ryan Multi-functional Food Safety Detector has been successfully installed and delivered at Yongcheng Yuxingda, with practical operation training completed.

To strengthen food safety supervision capabilities, Yongcheng Yuxingda Supply Chain Management Co., Ltd. introduced a multi-functional food safety detector developed by Shandong Lanende Intelligent Technology Co., Ltd. in September 2025. The installation, delivery, and hands-on training for the equipment have been completed. This collaboration aims to enhance Yuxingda's efficiency in food safety control within the supply chain through intelligent detection technology, ensuring compliance with national food safety standards.

Project Overview

Time: September 1–2, 2025

Location: Yongcheng City, Shangqiu City, Henan Province (Yuxingda Headquarters)

Participants:

Training Unit: Yongcheng Yuxingda Supply Chain Management Co., Ltd.

Equipment Supplier: Shandong Lanende Intelligent Technology Co., Ltd.

Core Equipment: Lanende Multi-functional Food Safety Detector (integrated with high-definition imaging, rapid detection, data analysis, and other functions, supporting testing for pesticide residues, microbial contamination, excessive additives, and other indicators).

Project Implementation Process

Lanende's technical team arrived at Yuxingda's laboratory to complete hardware assembly, software system deployment, and network connectivity for the detector.

Customized configuration of detection parameters and databases was performed based on Yuxingda's testing scenarios (e.g., agricultural products, processed foods).

Hands-on Training and Assessment

Theoretical Training: Lanende engineers explained the equipment principles, detection standards (e.g., GB 2763-2021 "National Food Safety Standard—Maximum Residue Limits for Pesticides in Food"), operational guidelines, and maintenance key points.

Practical Exercises: Yuxingda quality inspection personnel conducted on-site operations, including sample collection, simulated testing procedures, and data export, with one-on-one guidance and corrections from engineers.

Assessment and Acceptance: Trainees passed theoretical and practical evaluations, ensuring proficiency in operating the equipment.

Delivery and After-Sales Commitment

Signed equipment acceptance report and formally transferred the detector and supporting consumables.

Lanende provided a one-year free warranty, 24/7 remote technical support, and regular follow-up services.

Project Achievements

Efficiency Improvement: Testing time was reduced from 2–3 hours using traditional methods to within 30 minutes, significantly increasing daily testing capacity.

Data Accuracy: The equipment's detection results met Yuxingda's internal control standards.

Personnel Empowerment: Quality inspection personnel obtained certified operational qualifications through training and can independently conduct testing tasks.

Management Optimization: Detection data is uploaded in real-time to Yuxingda's supply chain management system, enabling traceability and riskearly warning).

Customer Feedback

"The intelligent design of Lanende's detector significantly reduces the difficulty of manual operations, and its multi-parameter detection (functionality) covers over 90% of our testing needs. The professionalism of the training team is also commendable, helping us quickly transition from traditional testing to digital management."

PrevEnhance research and medical testing capabilities! Jilin University Sino Japanese Friendship Hospital purchases ultrasonic disruptor

PrevEnhance research and medical testing capabilities! Jilin University Sino Japanese Friendship Hospital purchases ultrasonic disruptor NextJining Medical University Upgrades Research Hardware with Lanende Cell Disruptor

NextJining Medical University Upgrades Research Hardware with Lanende Cell Disruptor

Recent Articles

Albanian Customers Introduce Complete Set of Lanende Testing Equipment to Safeguard Quality Control at Slaughterhouses, Poultry Farms and Feed Mills

Angolan Customer Introduces Lanende Mycotoxin Detector to Guard Against Ochratoxin in Coffee Beans

Jining Medical University Upgrades Research Hardware with Lanende Cell Disruptor